Why Fast Delivery of Laser Safety Equipment Is Critical for Workplace Safety

The Importance of Timely Access to Laser Safety Equipment in High-Risk Environments

When there's a delay getting laser safety equipment, it really ramps up the chances of accidents happening in places like medical labs, factories, and research centers. A recent OSHA study from 2023 showed something pretty shocking actually: over half (about 62%) of all laser incidents happened because workers didn't have proper safety gear when they needed it. For those working in dangerous areas where lasers are used regularly, having everything ready goes hand in hand with staying safe. The protective stuff matters a lot too. Safety curtains for lasers, special glasses that block certain wavelengths, and those beam blockers need to be on site and accessible right from day one of any operation. Otherwise folks could end up exposed to serious hazards without even realizing what's happening.

Preventing Occupational Injuries with Immediate Availability of Laser Protective Eyewear (LPE)

Laser protective eyewear remains essential protection against serious eye damage from lasers, including harm to the retina and cornea. Research shows around 40 percent of all laser injuries happen during equipment setup or maintenance periods when workers simply don't have their protective glasses handy. Workplaces that stock up on laser safety goggles and arrange for quick delivery options experience fewer work stoppages due to eye injuries. These facilities also tend to follow the ANSI Z136.1 guidelines much better, which outline proper laser safety protocols across different industrial settings. Getting the right eye protection fast isn't just about compliance it actually saves time and money in the long run.

Case Study: How a Hospital Avoided Regulatory Penalties with 24-Hour PPE for Lasers Delivery

A Midwest hospital had a close call when someone almost got hurt by a Class 4 surgical laser during routine maintenance checks. Soon after, OSHA showed up unannounced for what looked like a compliance inspection. The hospital management scrambled to fix things quickly. They reached out to a local supplier who could deliver laser safety gear overnight. Within just one work shift, all the old protective eyewear and safety barriers were swapped out for compliant equipment. This quick thinking saved them from facing possible fines totaling around quarter of a million dollars. Most importantly, surgeries continued without interruption while staff felt much safer knowing their protection was up to standard. Fast delivery services really do matter when it comes to keeping workplaces safe and avoiding costly regulatory problems.

Laser Safety Equipment Types Available for Expedited Shipping

Laser Protective Eyewear (LPE): Wavelength-Specific Models with Fast-Track Shipping

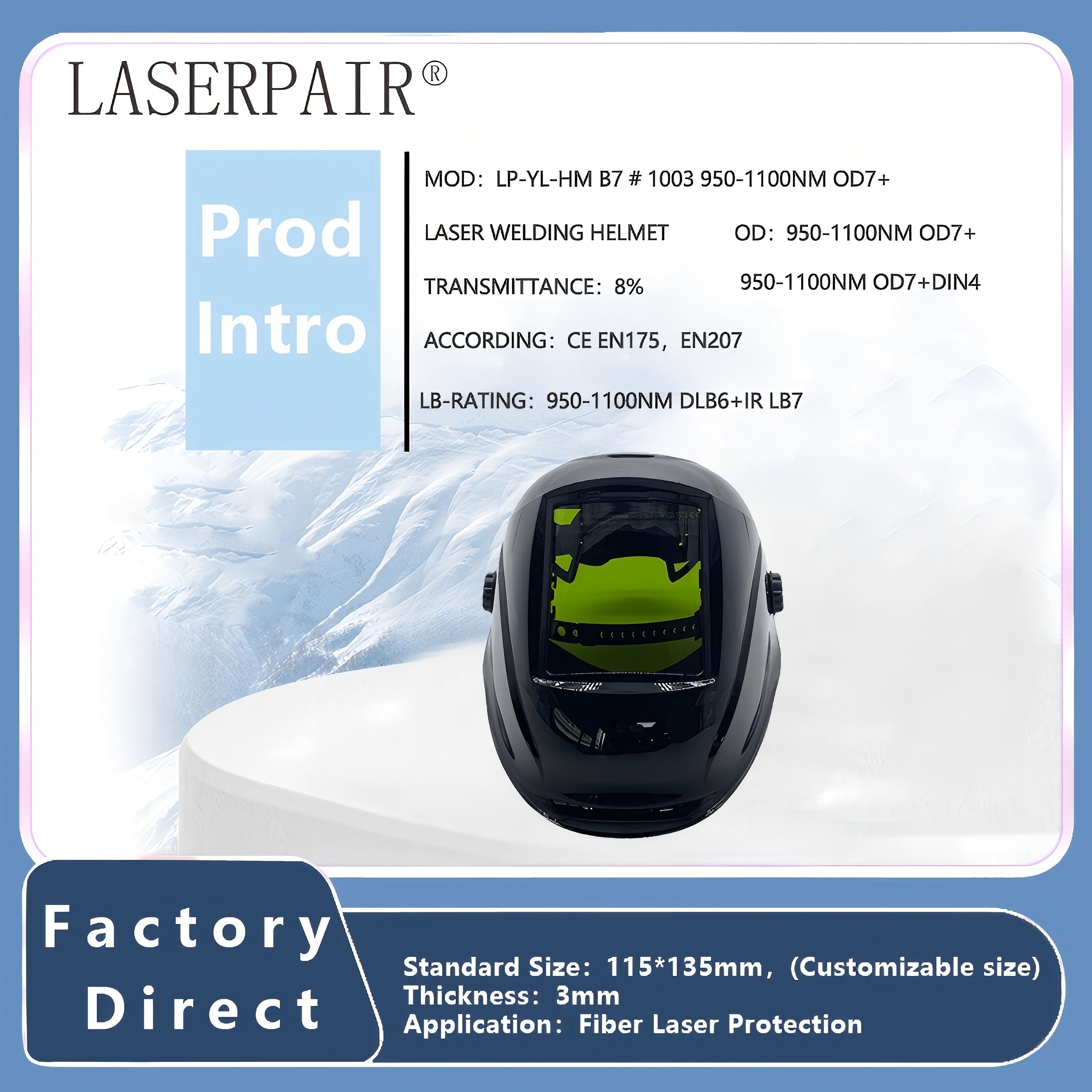

Critical for preventing retinal damage, laser protective eyewear must be matched precisely to the laser's wavelength used in industrial or medical applications. Modern suppliers offer ANSI Z136-compliant models with verified optical density ratings, shipping within 24–48 hours. For urgent replacements, select distributors maintain regionally stocked inventories of high-demand LPE, including models designed for 1064nm Nd:YAG and 10.6μm CO2 lasers, helping avoid operational delays.

Laser Safety Barriers and Curtains: Next-Day Dispatch for Temporary or Mobile Setups

Temporary laser workspaces require immediate deployment of Class 4-rated barriers capable of blocking diffuse reflections. Lightweight, flame-retardant polycarbonate curtains with 8–12 dB attenuation are now available via next-day air shipping to hospitals and research labs. These mobile solutions support last-minute facility reconfigurations while meeting OSHA 1926.102(a)(5) visibility requirements through orange or yellow tinted materials.

Complete Personal Protective Equipment (PPE) for Lasers: Express-Shipped Kits for Full Compliance

Comprehensive PPE kits—including LPE, face shields, and laser-resistant gloves—are available via 2-day shipping to meet evolving ANSI Z136.1–2022 compliance requirements. Pre-configured kits tailored for surgical or manufacturing environments come with wavelength validation cards and inspection checklists, enabling teams working with pulsed dye or ultrafast lasers to be quickly equipped and operationally safe.

Supply Chain Innovations Enabling Rapid Delivery of Laser Safety Equipment

Modern logistics strategies are transforming access to laser safety equipment, with three key innovations reducing lead times without compromising compliance.

Regional Distribution Hubs Stocked with High-Demand Laser Safety Equipment

The fulfillment centers we've placed around the country have 92 percent of laser safety equipment within 300 miles of where it's needed most. Think things like those special glasses for specific wavelengths or those adjustable protective barriers. According to that latest report on supply chain resilience from 2024, this setup cuts down ground shipping time to just 18 hours pretty much everywhere in the continental US. Medical facilities in places like Chicago? They get their ANSI Z136 compliant stuff from Michigan warehouses about two thirds quicker compared to waiting for shipments all the way from the other side of the country.

Just-in-Time Inventory Systems for Medical and Industrial Laser Facilities

When facilities combine advanced inventory tracking with vendor managed stock programs, they can keep their safety equipment stock really lean, usually around three days worth or less, without worrying about running out completely. According to a survey from last year, almost 8 out of 10 laser operators who implemented these kinds of systems stopped having to pay those expensive emergency air freight charges just to get replacement eye protection quickly. The system works pretty simply actually – whenever the inventory drops below certain levels set by the facility managers, it sends automatic alerts to order more supplies. This means workers stay protected all the time without anyone needing to constantly check what's in stock manually.

Balancing Speed and Compliance: Ensuring Fast Yet Regulated PPE for Lasers Delivery

Logistics companies are increasingly turning to blockchain technology for their documentation needs when it comes to handling OSHA requirements and customs inspections on rushed shipments. The latest data from the 2023 Industrial Procurement Survey suggests these new systems have reduced customs delays for imported laser curtains by around 40 percent, all while keeping detailed records available for audits. With automated checks built into the process, most expedited deliveries not only arrive faster but also pass through necessary safety regulations for laser equipment without any hiccups along the way.

Top E-Commerce Solutions for Quick-Ship Laser Safety Equipment

Online Platforms Offering Guaranteed 2-Day Shipping on Laser Protective Eyewear (LPE)

Top online retailers have built out their regional warehouses and smart inventory systems so they can deliver certified Laser Protective Eyewear within two days almost every time. A recent report from the E-Commerce Logistics Association showed that companies using those multi-channel inventory tools cut down on shipping delays by nearly two thirds when it comes to medical safety equipment. When doctors need protection during laser treatments, surgeons require specs for operating rooms, or factories need bulk orders, these e-commerce sites make sure they stock the most important wavelength ranges for LPE glasses, typically between 190 to 400 nanometers and again from 900 to 1700 nanometers. They also keep track of what's available in real time and bundle all the necessary paperwork for regulatory compliance right into each shipment.

Subscription Services for Routine Delivery of Laser Safety PPE

Hospitals and labs across the country have started switching to monthly subscriptions for their laser safety gear instead of buying in bulk. These services automatically send fresh supplies of protective barriers, safety curtains, and eye protection when needed. The system helps avoid those awkward situations where someone forgets to order new stuff before running out. According to recent surveys, around 9 out of 10 facilities that use this regular delivery method didn't get any citations from OSHA last year while following ANSI Z136.1 guidelines. Most places set their delivery schedules to match how often they check their equipment anyway, which makes audits easier since there's a paper trail showing staff were properly protected throughout the year.

FAQ

Why is fast delivery of laser safety equipment necessary?

Fast delivery ensures that workplaces can promptly equip themselves with necessary safety gear to prevent accidents and comply with regulatory standards.

What types of laser safety equipment can be quickly shipped?

Equipment such as laser protective eyewear, laser safety barriers, and comprehensive PPE kits are available for expedited shipping.

How do logistics innovations improve delivery efficiency of laser safety equipment?

Innovations such as regional distribution hubs and just-in-time inventory systems reduce shipping times and ensure consistent availability of safety gear.