Understanding the Risks of 532nm Green Laser Exposure

Why 532 nm Green Lasers Are Particularly Hazardous Due to High Visibility and Eye Sensitivity

Human eyes are most sensitive to light around 555 nanometers, which is why those green lasers at 532 nm seem way brighter than similar strength red or blue ones. People tend to stare at green laser beams for longer periods without even realizing how intense they actually are. The retina has these compounds called chromophores (like melanin) that soak up 532 nm green light about three times better than infrared light does. A recent study from 2024 looked at eye injuries caused by lasers and found something alarming: nearly two thirds of all cases involved green wavelengths. Even worse, most of these incidents resulted in lasting vision damage, especially when someone needed good contrast sensitivity for whatever task they were doing at the time.

The Science Behind Retinal Damage From 532nm Laser Exposure

532 nm lasers damage the retina through photochemical and thermal mechanisms:

- Photochemical effects: Interactions with retinal pigments generate reactive oxygen species, gradually degrading photoreceptor cells.

- Thermal effects: Rapid energy absorption raises retinal temperatures above 45°C, causing immediate coagulative necrosis in the retinal pigment epithelium.

A 2023 NIOSH analysis found that even low-power 5 mW green lasers can exceed safe exposure limits in under 0.25 seconds due to this wavelength’s biological efficiency.

Common Green Lasers (e.g., 532nm, Argon, KTP, Double YAG)

While 532 nm DPSS (diode-pumped solid-state) lasers dominate industrial and medical applications, other green wavelengths pose similar risks:

- Argon-ion lasers (514 nm): Used in research and dermatology

- KTP lasers (532 nm): Common in surgical procedures

- Double YAG systems (532 nm): Found in precision manufacturing

These lasers’ prevalence in critical fields underscores the necessity of wavelength-specific Laser Safety Glasses to mitigate occupational hazards.

Essential Features and Lens Materials in 532nm Laser Safety Glasses

Frame Design, Fit, and Peripheral Protection Considerations

Proper frame design ensures a secure seal against 532nm green laser reflections. Ergonomic wraparound styles reduce peripheral exposure gaps, while adjustable nose bridges and temple arms maintain fit during movement. Lab studies show up to 30% of workplace incidents occur due to poorly fitted eyewear allowing stray light penetration.

Visible Light Transmission (VLT) and User Comfort During Extended Wear

High VLT (50–80%) preserves color recognition for precision tasks while maintaining OD4+ protection at 532nm. A 2023 study found glasses with <40% VLT caused 72% of users to remove eyewear prematurely due to eye strain. For extended lab sessions, prioritize lenses balancing 80% VLT with OD7+ attenuation.

Comparison of Lens Materials: Polycarbonate, Glass, and Dielectric-Coated Options

| Material | OD Range (532nm) | Weight (g) | Impact Resistance | Best For |

|---|---|---|---|---|

| Polycarbonate | OD4–OD6 | 35–45 | High | Industrial maintenance |

| Glass | OD5–OD7 | 50–65 | Moderate | Medical/QC applications |

| Dielectric-coated | OD7+ | 40–55 | Low | High-power lab lasers |

Dielectric coatings enable OD7+ protection through wavelength-specific interference layers while retaining 70% VLT.

Selecting the Right Lens Material for Your Environment (Industrial vs. Lab)

Industrial settings demand polycarbonate for impact resistance during equipment maintenance, while labs using Class 4 532nm lasers require dielectric-coated lenses. OSHA mandates OD7+ eyewear for lasers exceeding 500mW, necessitating material choices aligned with operational hazards.

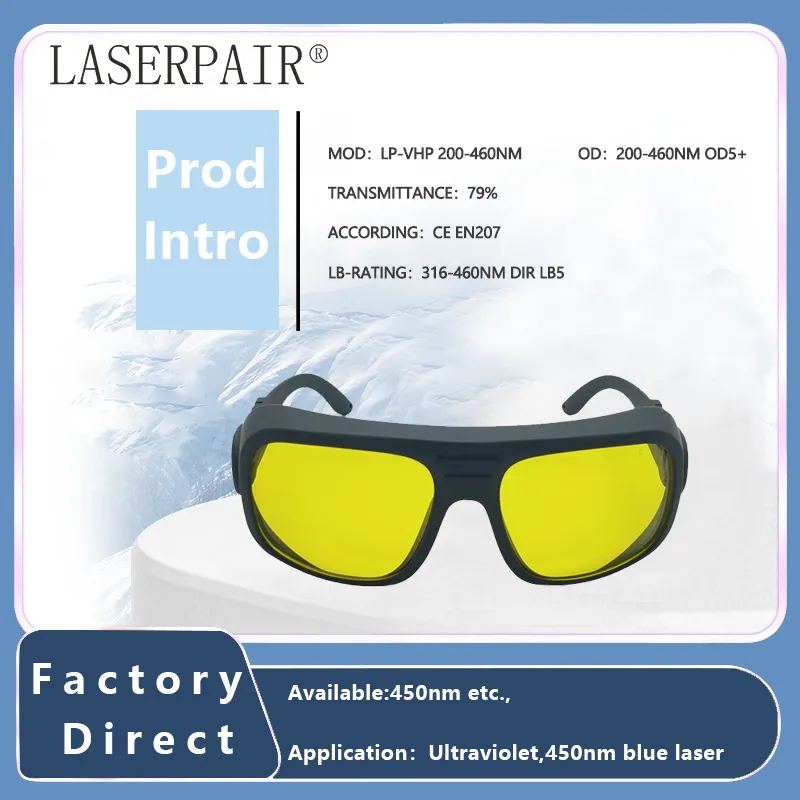

Certification Standards and Compliance for Reliable Protection

ANSI Z136 vs. EN 207: Comparing Key Certification Standards for Laser Safety Glasses

When selecting laser safety glasses for 532nm green lasers, compliance with ANSI Z136 (U.S. standard) or EN 207 (European norm) is non-negotiable. ANSI Z136 focuses on optical density (OD) verification through controlled lab testing, while EN 207 requires live laser exposure tests simulating real-world hazards. Key differences include:

| Standard | Region | Testing Method | Certification Mark Requirement | Best For |

|---|---|---|---|---|

| ANSI Z136 | North America | Spectral transmission measurement | OD rating at specific wavelengths | Lab and medical settings |

| EN 207 | Europe | Direct laser beam exposure | Wavelength + OD + "L" or "D" markings | Industrial applications |

EN 207-certified glasses undergo pulsed and continuous wave laser tests, making them ideal for environments with variable 532nm laser intensities.

How to Verify Legitimate Certifications on Product Labels

Authentic laser safety glasses display embossed (not printed) certification markings:

- ANSI-compliant pairs show "Z136" and exact wavelength/OD (e.g., "532nm OD6+")

- EN 207 labels include a shield icon with "D" for pulsed lasers or "L" for continuous beams.

Always cross-check certification numbers with the manufacturer’s online database—counterfeit eyewear often uses expired or fabricated credentials.

Rising Demand for Dual-Certified Eyewear in Global Research and Industrial Settings

73% of laser safety officers now require dual-certified (ANSI Z136 + EN 207) glasses for 532nm protection, driven by international research collaborations and multinational manufacturing standards. A 2023 Laser Institute survey found dual-certified models reduce procurement errors by 41% in facilities handling Class IV green lasers, while ensuring seamless compliance across regulatory jurisdictions.

Top-Rated Laser Safety Glasses for 532nm and Common Selection Mistakes

Top-Rated Safety Goggles for 532nm Green Lasers in 2024

For those working with 532nm green lasers, top quality safety glasses today offer an impressive OD7+ rating along with protection across multiple wavelengths from 180 to 540 nanometers. The best models on the market right now typically come equipped with polycarbonate lenses that resist scratches plus wraparound designs which stop about 99% of unwanted light coming in from the sides. Most professionals would agree that glasses certified under both ANSI Z136 and EN 207 standards are really taking over the 2024 buying guide lists because these standards ensure actual protection when dealing with dangerous laser reflections or direct beam exposure during work tasks.

Common Mistakes When Selecting Laser Safety Glasses and How to Avoid Them

A 2023 Journal of Occupational Health study found 63% of laser eye injuries stem from these errors:

- Wavelength mismatches – Assuming “green laser” labels guarantee 532nm compatibility without verifying specs.

- Cost-driven compromises – Selecting eyewear with OD ratings below OSHA’s minimum requirement of OD4 for Class 3B+ lasers.

- Poor fitment – Neglecting adjustable nose bridges/temples, enabling scattered beam exposure.

Expert-Recommended Brands and Where to Purchase Certified 532nm Protection

Trusted suppliers prioritize LB6+ DIRM-certified models, which withstand pulsed 532nm lasers up to 10 J/cm². Purchase only from distributors providing third-party test reports, wavelength-specific OD verification, and compliance documentation for your regional standard (ANSI or EN).

Controversy Analysis: Overestimating OD Protection in Low-Cost, Uncertified Eyewear

Studies show 40% of budget “laser-safe” glasses fail to meet advertised OD levels at 532nm. Non-certified alternatives often use untested dyes that degrade protection by ≈80% within six months—a critical risk factor in medical/lab environments.

Frequently Asked Questions (FAQ)

What makes 532nm green lasers more dangerous compared to other colors?

Green lasers at 532 nm are particularly hazardous because human eyes are most sensitive to this wavelength, making them appear much brighter than other colors. Increased eye sensitivity can lead to longer exposure times without realizing their intensity, contributing to a higher risk of retinal damage.

What is Optical Density (OD), and why is it important for laser safety?

Optical Density (OD) is a measure that quantifies how effectively laser safety glasses can attenuate specific wavelengths of light. For 532nm green lasers, each unit of OD reduces transmitted laser energy tenfold, providing necessary protection by lowering the intensity of dangerous laser beams.

Why are dual-certified laser safety glasses important?

Dual-certified laser safety glasses are important because they meet both ANSI Z136 (U.S. standard) and EN 207 (European norm) requirements, ensuring comprehensive protection against laser exposure. They are necessary for international research and multinational manufacturing settings to ensure safety compliance.