Understanding CE Certification and Its Role in Laser Safety Compliance

What Is CE Certification and Why It Matters for Laser Safety Products

The CE mark is required for all laser safety gear sold throughout Europe, showing that these products meet strict EU rules on health, safety, and environmental protection. The certification process aligns with important regulations like the Machinery Directive from 2006 and the Low Voltage Directive updated in 2014, both of which set standards for containing hazards and protecting workers during operation. Manufacturers who get their products certified show they've gone through thorough testing procedures, which opens doors to selling across EU countries without running into legal problems. Plus, companies avoid getting stuck with expensive lawsuits if their equipment doesn't follow safety guidelines. Products lacking proper CE marking simply aren't allowed on EU shelves at all, which puts actual workers at risk when using substandard laser protection equipment in industrial settings.

CE Marking and Its Significance for Product Safety in the EU

The CE mark represents a manufacturer's official promise that their product complies with all relevant EU safety standards. When applied to laser safety gear specifically, this certification confirms essential safeguards like protection against harmful radiation exposure, adequate electrical insulation, and structural integrity under stress conditions. Products bearing the CE mark can move freely throughout EU member states and EEA territories without facing extra checks at borders, which simplifies international trade significantly for companies. But getting caught misusing the mark - especially putting it on products that haven't undergone proper evaluation - carries serious repercussions. The EU has been cracking down hard lately, imposing fines reaching as high as 500,000 euros according to recent data from 2023, along with forced removals of non-compliant items from market shelves. For anyone involved in manufacturing or selling safety equipment, understanding these regulations isn't just good practice; it's absolutely vital for maintaining business credibility and avoiding costly legal troubles down the road.

Compliance with EU Health, Safety, and Environmental Protection Standards

Laser safety products must comply with harmonized European standards such as EN 60825-1 (laser radiation safety), EN 207 (protective eyewear performance), and the RoHS directive on restricted hazardous substances. These standards require:

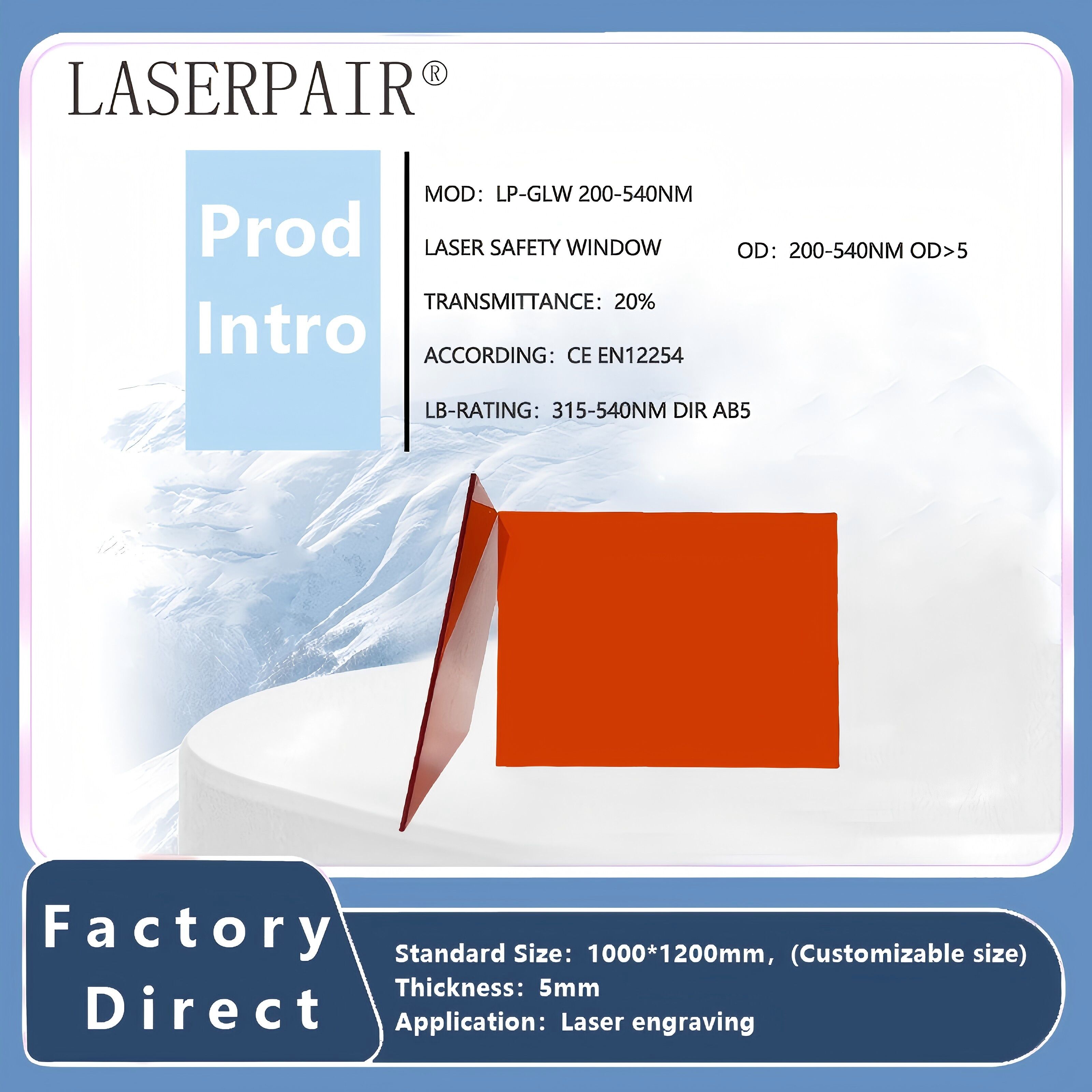

- Sufficient optical density (OD) to block specific laser wavelengths

- Frame durability under high-intensity exposure, validated through tests like 10-second bursts at 100 W/cm²

- Elimination of lead, mercury, and other toxic materials from components

Meeting these criteria ensures both user safety and environmental responsibility while supporting interoperability across industrial systems. Non-compliance invalidates CE certification and may trigger enforcement actions under the EU Product Liability Directive.

Key Regulatory Standards for CE Certification of Laser Safety Products

EN 60825-1 and IEC 60825-1: Laser Safety Classification and Equipment Requirements

Getting CE certification means following both EN 60825-1 and IEC 60825-1 standards. These standards put lasers into four different risk categories from class 1 to class 4, each needing specific safety measures. The latest changes in 2024 have made things stricter regarding safety features like emergency shut off systems, warning lights showing when lasers are active, and ways to reduce laser intensity if needed. Take class 4 lasers as an example they now need automatic power cut offs whenever their protective housing gets damaged or opened. Back in 2021 there was another important change to EN 60825-1 that brought it in line with EU electrical safety rules. This helps keep safety practices uniform whether someone is working with lasers in hospitals, factories, or even at home with consumer products.

EN 207 and EN 208: Performance Standards for Laser Protective Eyewear

The EN 207 standard establishes what safety glasses need to do when facing laser light, particularly how they handle direct exposure from beams including those pulsed lasers reaching as high as 100 MJ per square centimeter. For everyday work around weaker laser sources, there's another standard called EN 208 which covers alignment goggles designed specifically for these lower power applications. To make sure products meet these requirements, independent labs across Europe conduct tests according to strict protocols. These tests involve subjecting equipment to harsh conditions like accelerated aging where items spend 500 straight hours at 55 degrees Celsius and 85 percent humidity. They also check for any distortion in the lenses and run various mechanical stress tests outlined in the EN 207 specifications to confirm everything works properly under real world conditions.

Optical Density (OD) and LB Ratings in CE-Marked Laser Protection

| Parameter | EN 207 Requirement | Typical Laser Application |

|---|---|---|

| OD ≥ 4 | Blocks 99.99% of 1064 nm Nd:YAG beams | Industrial cutting (Class 4) |

| LB Rating 5 | Resists 10-second exposure at 10 kW | Medical dermatology lasers |

| Optical density measures light absorption capability, while LB ratings indicate resistance to laser-induced damage. CE-marked eyewear must clearly display both values for each protected wavelength to ensure correct selection and safe use. |

Pulse Frequency Classifications (D, I, R, M) Under EN 207

- D (Continuous Wave): Protection against steady beams, such as CO₂ lasers in manufacturing

- I (Single Pulse): Designed for Q-switched lasers used in tattoo removal

- R (Repetitive Pulse): Suitable for pulsed fiber lasers operating between 10–1000 Hz

-

M (Mode-Locked): Covers ultrafast femtosecond lasers in ophthalmic procedures

These classifications ensure that protective eyewear matches the temporal characteristics of the laser source, providing targeted defense against specific pulse types.

Testing, Assessment, and Conformity Procedures for CE Marking

Conformity Assessment Routes for Laser Safety Products

How products get certified really hinges on how risky they are considered to be. For items deemed low risk, like most Class 1 and 2 devices, manufacturers can basically handle their own certification process as long as they maintain proper internal controls and keep all the necessary technical records in order. Things get more complicated when dealing with higher risk categories such as Classes 3B and 4. These need approval from one of those official EU Notified Bodies who will actually look at the design details and conduct thorough quality checks. The CE marking can't go on until this whole process is completed successfully, which makes sense given what's at stake for both consumers and businesses alike.

Testing Process for CE-Certified Laser Safety Eyewear and Components

Comprehensive optical and mechanical testing is essential for CE compliance. Key procedures include:

- Optical Density (OD) Validation: Confirming lenses block target wavelengths at specified levels

- Beam Alignment Checks: Ensuring consistent protection across viewing angles

- Frame Integrity Tests: Evaluating structural resilience under load

Manufacturers must engage accredited labs to conduct EN 207-mandated tests and maintain full records in their technical files.

Frame and Lens Durability Testing Under EN 207 Conditions

EN 207 specifies three core durability tests:

- Impact Resistance: Lenses must withstand a 150g steel ball dropped from 1.3m

- Temperature Cycling: Exposure to ±40°C cycles without optical degradation

- Surface Abrasion: 100 cycles using standardized sand and rubber eraser methods

Products passing these assessments receive LB ratings indicating their resistance to continuous (LB 1–10) or pulsed (LB 1–10D) laser exposure.

Role of Independent Testing and Notified Bodies in Verification

Organizations like TÜV SÜD carry out surprise visits to factories to check if production remains consistent over time. During these checks, inspectors look at how materials are tracked throughout the process, examine the way batches get tested, and inspect records showing when measuring instruments were last calibrated. This kind of monitoring helps maintain regulatory standards. At the end of all this work comes the CE certificate, usually good for about five years before needing renewal through another round of qualification tests. For companies wanting to stay compliant without constant hassle, understanding this certification cycle becomes pretty important.

Manufacturer Responsibilities: Technical Documentation and Declaration of Conformity

Essential Technical Documentation Required for CE Certification

For products carrying the CE mark, manufacturers need to put together detailed technical files showing they meet all necessary requirements. These files typically contain things like design blueprints, MSDS documents, completed risk assessments, plus various test reports that confirm standards such as EN 60825-1 and EN 207 have been met. The documentation should explain which conformity assessment pathway was followed throughout development, along with how quality checks were implemented during actual manufacturing runs. Two particularly important aspects worth highlighting are the verification of optical density levels and the results from EN 207 durability testing. As per European Union regulations, companies are required to keep these records available for inspection for no less than ten full calendar years following when the final batch of units leaves the factory floor.

Preparing a Valid EU Declaration of Conformity for Laser Safety Products

The EU Declaration of Conformity (DoC) is a legal statement affirming that the product meets all relevant EU directives. It must specify:

- Product identification (model, serial, or batch numbers)

- Applicable legislation (e.g., PPE Regulation 2016/425)

- Harmonized standards applied (e.g., EN 207, EN 208)

- Identification of the Notified Body, if involved

Omitting key details such as pulse frequency classifications (D/I/R/M) or LB ratings may delay regulatory approval and market entry.

Ensuring Ongoing Compliance and Traceability in Manufacturing

Once certified, manufacturers need to keep track of every component and raw material down to specific batches. This tracking system ensures accountability throughout production processes. Companies should conduct internal audits on an annual basis and update their technical files whenever there are design changes. Think about things like changing lens coatings or switching out frame materials these kinds of modifications require proper documentation to stay compliant. When major changes happen, products need to go through retesting according to EN 207 standards for both heat resistance and mechanical strength tests. Staying up to date with what's published in the EU Official Journal is also important work for manufacturers wanting to spot upcoming standard revisions early enough to adjust operations accordingly while keeping pace with evolving PPE regulations across Europe.

FAQ

What is CE certification?

CE certification confirms that laser safety products comply with EU regulations on health, safety, and environmental protection.

Why is CE marking important for laser safety gear?

CE marking ensures products meet EU standards, allowing for free movement within the EU and avoiding legal issues.

What standards are involved in CE certification for laser safety?

Key standards include EN 60825-1 for laser radiation safety and EN 207 for protective eyewear performance.

What does Optical Density (OD) indicate?

OD measures the light absorption capability of laser protective eyewear.