Understanding Laser Safety Windows and Their Role in Hazard Protection

Laser safety windows are engineered barriers designed to protect workers from hazardous radiation while enabling visual oversight of laser processes. These specialized windows use wavelength-specific optical filters to block harmful energy levels, making them critical for facilities using Class 3B/4 lasers.

What Are Laser Safety Windows and How Do They Function?

Constructed from acrylic or glass with laser-attenuating coatings, these windows absorb or reflect targeted wavelengths. For example, a window rated for 1064 nm lasers prevents infrared radiation transmission while maintaining 80%+ visible light clarity. Their multi-layer design often includes anti-reflective surfaces to prevent beam scattering.

The Importance of Laser Safety Windows in Protecting Against Laser Radiation

Unfiltered laser exposure causes irreversible retinal damage within 0.25 seconds at 1W power (OSHA 2023). Safety windows reduce radiation below maximum permissible exposure (MPE) limits through optical density (OD) ratings. An OD 6 window attenuates 10⁶ times more energy than unprotected glass, effectively blocking 99.9999% of harmful wavelengths.

Function and Design of Laser Safety Filters and Windows

Key design considerations include:

- Wavelength specificity: Matching filter coatings to laser emissions (e.g., 355 nm UV vs. 10.6 μm CO₂ lasers)

- Impact resistance: 5/8" polycarbonate layers for debris protection in industrial settings

- Ergonomic integration: Frameless designs for easy retrofitting into existing enclosures

Recent Adapt Laser studies (2025) show properly maintained windows reduce PPE dependency by 63% in fiber laser applications while maintaining ANSI Z136.1 compliance.

Laser Safety Windows as Critical Engineering Controls for Class 4 Lasers

Class 4 Laser Safety: Risks and the Role of Engineering Controls

Class 4 lasers produce power levels above 500 mW and can cause serious issues including immediate skin burns, lasting damage to the retina, and even start fires from both direct exposure and scattered light beams according to ANSI Z136.1-2022 standards. These aren't your typical low power lasers. For proper safety, they need strong engineering solutions such as special laser safety windows that help contain the beam first before anything else happens. Many top manufacturers are starting to build wavelength specific windows right into their equipment enclosures. This clever design actually transforms dangerous Class 4 systems into much safer Class 1 operations when everything runs normally. What this means is fewer accidents caused by people forgetting safety procedures since the protection becomes part of the machine itself rather than something extra that operators have to remember all the time.

Mitigating Eye and Skin Health Risks Through Wavelength-Specific Protection

Safety windows for lasers work with special coatings that either soak up or bounce back certain light wavelengths. Think about those 1064 nm fiber lasers all the way up to the 10.6 micrometer CO2 systems. Take polycarbonate windows as an example they stop around 90 percent of that near infrared stuff but still let through enough visible light so operators can actually see what's going on during procedures. What makes these filters really effective is their ability to knock down ambient laser radiation levels under 5 watts per square meter which meets the maximum permissible exposure limits outlined in the IEC 60825 standard. This compliance isn't just paperwork it actually protects workers from harmful exposure levels day after day.

Reducing Reliance on PPE with Integrated Laser Safety Solutions

Safety goggles still play an important role when doing maintenance work, but modern engineered barriers have cut down how much PPE staff need to wear day to day. According to a recent industry report from 2023, companies that installed certified laser safety windows saw their workers wearing goggles 70% less often during regular tasks. What's really interesting is how combining these safety windows with just the right PPE for specific jobs actually follows the control hierarchy recommended by both OSHA and ISO standards. Many plants have found this combination works better than relying solely on traditional protective gear.

Prevention of Eye Damage and Skin Burns Using Engineered Barriers

Windows made from multiple layers of acrylic or glass rated at OD 6+ can stop almost all laser energy - we're talking about blocking 99.9999% of what hits them even when dealing with lasers up to 20 kW in power. Testing in labs shows these protective barriers hold up after many 10 second bursts without showing any signs of wear, which is really important because otherwise they could fail over time from heat buildup. Putting these windows strategically around where people work helps create areas free from reflections, something that makes a big difference since most laser accidents actually happen from indirect exposure. According to NIOSH data from 2021, this kind of secondary exposure accounts for about three quarters of all incidents in the field.

Optical Performance: Ensuring Visibility Without Compromising Safety

Enabling Safe Visual Inspection with High-Clarity Laser Safety Windows

The latest laser safety windows are made from stuff like coated polycarbonate and laminated glass, letting through around 85% of visible light but stopping those dangerous wavelengths. Techs can watch laser operations happen right before their eyes without getting exposed directly, which is really important when working on precision manufacturing jobs where seeing things properly affects the final product quality. Take CO2 lasers for instance, when paired with OD 4+ windows, they cut down on accidental exposure problems by roughly 70% compared to old school ways of looking at what's happening inside (according to Laser Systems Journal from last year).

Non-Reflective Surfaces and Strategic Workplace Design to Minimize Reflection Hazards

Using anti reflective coatings along with matte finish window frames can reduce those pesky stray light reflections by around 90 percent, which tackles one of the main causes behind indirect laser injuries. Many facilities take extra steps too, like positioning their windows at angles between 15 and 30 degrees away from where people work, plus installing baffle walls that help keep those scattered beams contained. According to what most industrial safety manuals recommend, combining these different methods actually stops about a third of all laser related accidents in workplaces that happen because of those unpredictable reflections bouncing around.

Balancing Operational Efficiency and Laser Safety in Daily Workflows

Modular window designs with quick-release mechanisms allow maintenance access in under 3 minutes, maintaining safety protocols without disrupting production schedules. Facilities report 12% faster changeovers when integrating these solutions with automated beam-shuttering systems, proving that robust safety measures can coexist with lean manufacturing principles.

Material Selection: Acrylic vs. Glass Laser Safety Windows

Acrylic vs. Glass: Pros and Cons for Different Industrial Environments

When it comes to laser safety windows, acrylic and glass each have their own strengths depending on what the situation calls for. Acrylic is great for places where there might be bumps and bruises since it doesn't shatter easily. That makes it a good choice for factory floors where equipment moves around a lot and accidents can happen. Glass on the other hand is definitely heavier but stands up better to scratches and lets through almost all the light (over 99%). Labs that need clear views without distortion often go with glass instead. According to some recent testing from 2023, acrylic actually handles impacts about three times better than regular tempered glass. However, when exposed to UV light over long periods, glass tends to hold together longer without breaking down. So the choice really depends on whether impact resistance or long term stability matters most for the application at hand.

Impact Resistance, Optical Clarity, and Long-Term Durability

| Factor | Acrylic | Glass |

|---|---|---|

| Impact Resistance | High (shatter-proof) | Moderate (if tempered) |

| Optical Clarity | 92% light transmission | 99% light transmission |

| Lifespan | 5–15 years | 15–30 years |

| Weight | 50% lighter | Heavy |

| Acrylic's lightweight nature reduces installation complexity, while glass's rigidity suits static, high-power laser setups. However, acrylic degrades faster under prolonged UV exposure, requiring replacement 2–3x more frequently than glass in outdoor applications. |

Cost-Benefit Analysis: Initial Investment vs. Lifecycle Value

Acrylic costs 40–60% less upfront than glass, but its shorter lifespan increases long-term expenses in high-usage settings. For example, a 2024 market analysis showed glass systems achieve 35% lower total ownership costs over 10 years in research labs, while acrylic proves economical in short-term industrial projects.

Industry Trends: Lightweight Acrylics vs. Heavy-Duty Glass Applications

The move to modular laser systems is making acrylic windows increasingly popular in cars and planes because lighter materials mean better performance on the road and in the air. On the flip side, the medical field and semiconductor manufacturing still rely heavily on glass. Why? Because these industries need crystal clear visibility and must follow strict safety rules outlined in ANSI Z136.1 for handling dangerous Class 4 lasers. We're starting to see some interesting combinations lately though. Manufacturers are experimenting with hybrid designs that take advantage of acrylic's toughness while adding protective glass coatings. These new setups work well when dealing with multiple wavelengths at once, something many advanced applications require today.

[Industry benchmarks]: Materials Performance Report

Selecting and Deploying Laser Safety Windows for Compliance and Real-World Performance

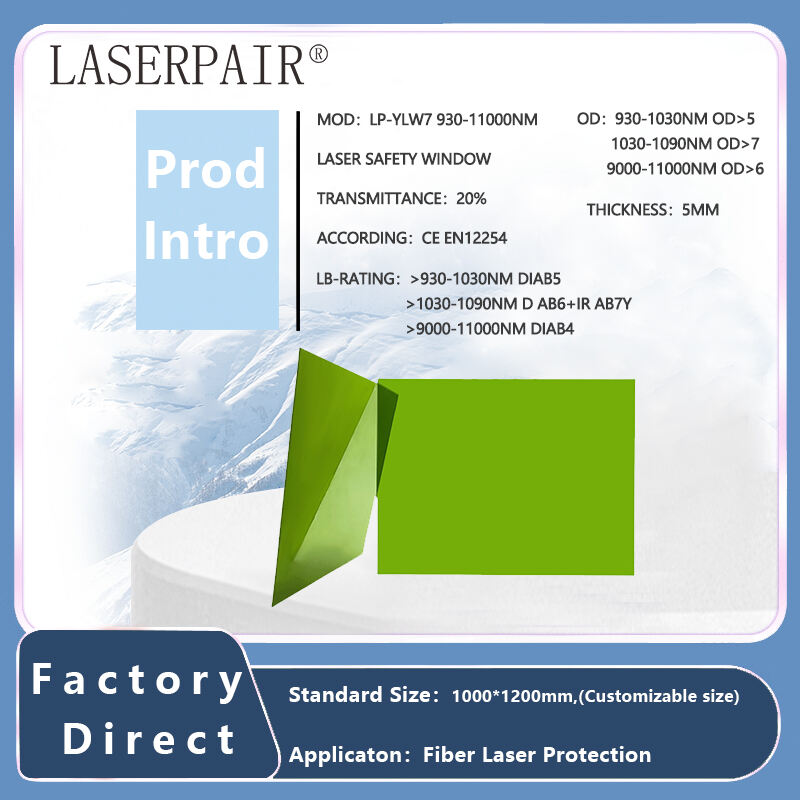

Key Selection Criteria: Laser Wavelength, Power, and Required Optical Density (OD)

Getting things right starts by making sure the window specs match what the laser needs. When working with those pulsed CO2 lasers running around 10.6 microns, polycarbonate windows rated at OD 4 or higher usually work fine. But for fiber lasers operating near 1,070 nanometers, most folks find they need acrylic filters with at least OD 6 rating to handle power levels above 100 watts per square centimeter. And remember something important too: double check all these numbers against the Maximum Permissible Exposure guidelines before proceeding with any setup.

Matching Laser Classes with Appropriate Safety Window Specifications

Class 4 lasers (≥500 mW continuous) demand windows with:

- Wavelength-specific absorption ≥99.9999% (OD 6+)

- Impact resistance against 1064 nm fiber laser beams at 6 J/cm²

- Non-bleaching materials for UV excimer lasers (248-351 nm)

Applications Across Medical, Manufacturing, and Research Laboratory Settings

In operating rooms, 808 nm diode laser windows enable real-time visual monitoring during lipolysis procedures. Automotive manufacturers using 6 kW fiber lasers employ multi-layer coated windows that maintain 92% visible light transmission while blocking infrared radiation.

Case Study: Implementing OD 6+ Windows in a High-Power Fiber Laser Facility

A Tier 1 aerospace supplier reduced reflection hazards by 78% after installing custom wavelength-tuned acrylic windows in their 12 kW laser welding cell (Laser Institute of America Case Study, 2023). Post-installation audits confirmed compliance with OD 7 requirements for 1,070 nm exposure.

Meeting Compliance Standards: ANSI Z136 and IEC 60825 Requirements

Certified windows must pass:

- ANSI Z136.1-2022: 10-second exposure survival at maximum irradiance

- IEC 60825-1:2022: Spectral transmittance <0.001% at specified wavelengths

- NFPA 70E: Arc flash protection for laser-initiated plasma events

Audits, Labeling, and Documentation for Regulatory Readiness

Maintain records of:

- Annual OD verification tests (±0.1 tolerance)

- Inspection logs for surface degradation (scratches >0.5 mm require replacement)

- Wavelength-specific certification labels per 21 CFR 1040.10

Frequently Asked Questions

What are laser safety windows made of?

Laser safety windows are typically made of acrylic or glass materials that include laser-attenuating coatings designed to absorb or reflect specific wavelengths.

How do laser safety windows protect workers?

These windows reduce laser radiation to levels below maximum permissible exposure limits by blocking harmful wavelengths using optical density ratings.

Why are laser safety windows essential for Class 4 lasers?

Class 4 lasers emit high power levels and pose significant risks such as skin burns and eye damage, making specialized laser safety windows critical for containment and protection.

What factors influence the choice between acrylic and glass laser safety windows?

The choice between acrylic and glass depends on factors like impact resistance, optical clarity, weight, and long-term durability.

How often should laser safety windows be inspected?

According to industry standards, laser safety windows should be inspected annually for optical density verification and surface degradation.

Table of Contents

- Understanding Laser Safety Windows and Their Role in Hazard Protection

- Laser Safety Windows as Critical Engineering Controls for Class 4 Lasers

- Optical Performance: Ensuring Visibility Without Compromising Safety

- Material Selection: Acrylic vs. Glass Laser Safety Windows

-

Selecting and Deploying Laser Safety Windows for Compliance and Real-World Performance

- Key Selection Criteria: Laser Wavelength, Power, and Required Optical Density (OD)

- Matching Laser Classes with Appropriate Safety Window Specifications

- Applications Across Medical, Manufacturing, and Research Laboratory Settings

- Case Study: Implementing OD 6+ Windows in a High-Power Fiber Laser Facility

- Meeting Compliance Standards: ANSI Z136 and IEC 60825 Requirements

- Audits, Labeling, and Documentation for Regulatory Readiness

- Frequently Asked Questions