Understanding Laser Hazard Classification and Risk Prioritization

ANSI Z136.1 and IEC 60825 Frameworks: Core Principles for Research Labs

Laser safety in research environments primarily follows guidelines from ANSI Z136.1 and IEC 60825 standards. These regulations categorize lasers into four different risk levels depending on their emission limits (AEL) and what's considered safe exposure (MPE). Labs typically deal with Class 1 lasers that don't really pose much danger under normal circumstances, but things get serious with Class 4 devices. These high-power lasers can cause permanent eye damage, burn skin tissue, and even start fires, so they need strict control measures. To stay compliant, researchers must put in place proper safety equipment tailored to specific wavelengths, especially for Class 3B and 4 lasers where beam path enclosures are essential. Calculating and recording the nominal ocular hazard distance (NOHD) becomes part of routine work too. Formal assessments of potential hazards should happen at least once every year or two. All these steps help keep the lab's safety protocols current as experiments change over time, which ultimately forms the basis for good laser safety practices across most research facilities.

Why Class 3B Lasers Drive Disproportionate Incident Rates in Academic Settings

Class 3B lasers (5–500 mW continuous wave) account for over 60% of academic lab incidents despite comprising only 30% of installed systems. This imbalance arises from three interrelated factors:

- Accessibility vs. hazard mismatch: Their moderate power enables broad experimental utility but delivers sufficient energy for immediate retinal damage upon direct or specular reflection exposure

- Training gaps: High turnover among student researchers often results in insufficient supervised practice with alignment procedures and hazard recognition

- Interlock vulnerabilities: Frequent temporary bypasses—intended to support rapid prototyping or diagnostics—undermine engineered safeguards

A 2023 multi-university audit found Class 3B units experienced three times more interlock override incidents than Class 4 systems. To address this, leading institutions now mandate optical density (OD) verification prior to beam alignment and enforce laser-controlled area (LCA) authorization protocols requiring LSO approval before system access.

Engineering Controls: Design, Validation, and Real-World Reliability

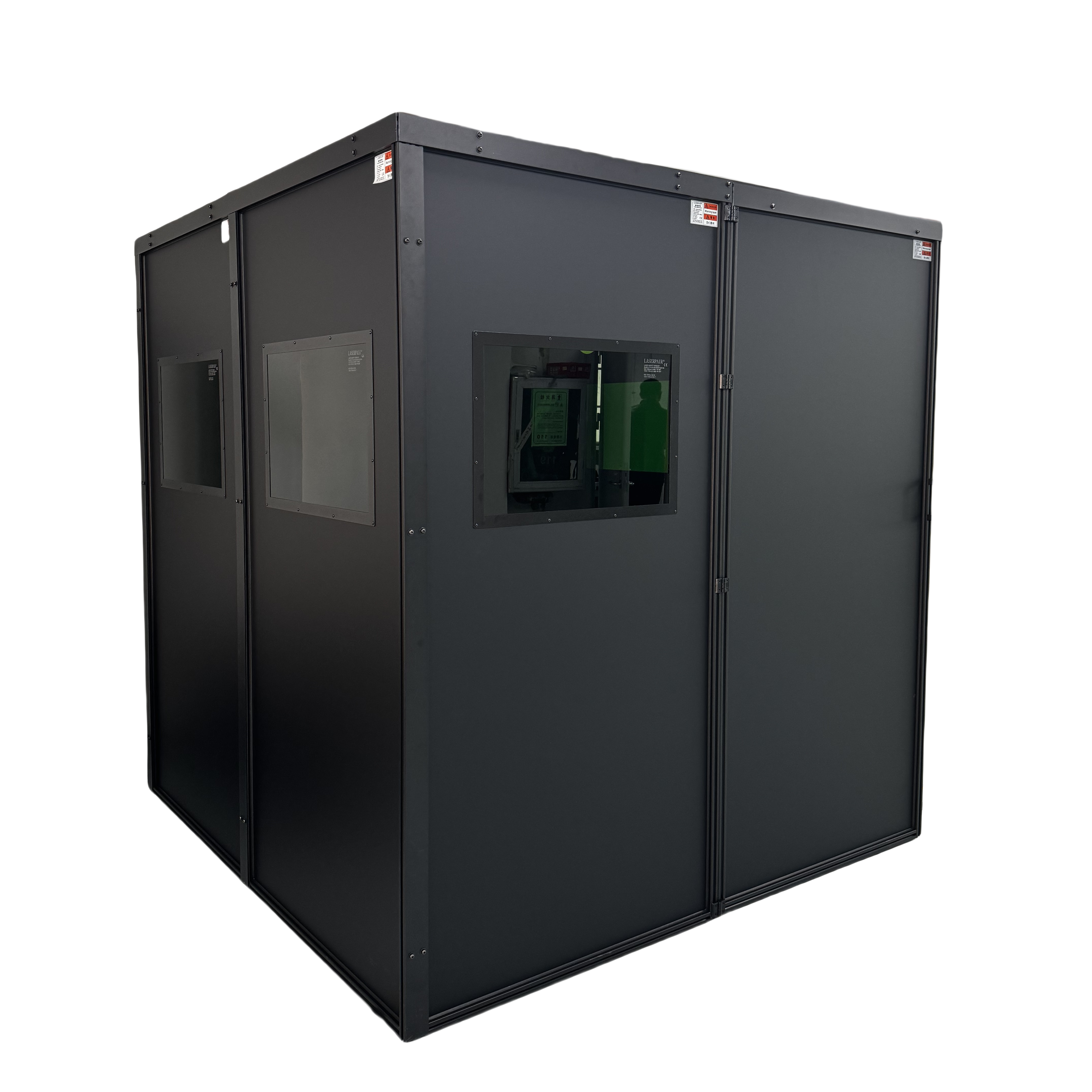

Beam Enclosures, Interlocks, and Permanent Barriers: Key Design Metrics and Compliance Checks

Good engineering controls really come down to solid design specs and regular checks that everything still works properly. When it comes to beam enclosures, they need to block those target wavelengths at least 99.9% of the time, which translates to an optical density of 3 or better. The interlock systems are just as critical too. These safety circuits have to shut off laser emissions within half a second if someone opens up the enclosure unexpectedly. Three main things determine compliance standards in practice. First, how well barriers hold up against penetration tests at 10 joules per square centimeter for Class 4 lasers. Second, the reliability of those interlock responses needs to hit around 99.95% success during testing. And third, materials used for optical components should maintain their effectiveness for at least a decade even when exposed to UV light over time. Most problems we see actually happen because engineers miss those tiny thermal expansion gaps between parts of the enclosure or install cheap non-latching relays instead of proper ones. According to a study published last year in the Journal of Laser Applications, these simple oversights account for nearly 4 out of every 10 accidents in university labs. For quarterly maintenance checks, technicians typically run calibrated power meters behind all protective barriers and go through each possible failure scenario with the interlock system to make sure nothing slips through the cracks.

Interlock Bypass Analysis: Lessons from University Lab Incidents (2020–2023)

Looking at university incident reports between 2020 and 2023 shows we still have problems with people messing up safety controls in engineering setups. When it comes to those dangerous Class 3B/4 laser injuries, around 6 out of 10 happened because someone bypassed the safety locks without permission. Most often folks used simple tricks like sticking magnets on them, taping over parts, or even rewriting the firmware just so they could keep working without stopping. There seem to be three main issues causing these problems. First, many labs only do safety training once a year instead of every three months as recommended. Second, most facilities don't have proper tamper proof seals on their equipment. And third, sensors get neglected until something breaks down. Interestingly enough, physics departments had about three times more bypass incidents compared to engineering labs, which tells us that different departments handle safety rules differently based on their culture. To fix things up, schools are starting to install magnetic detectors right into the lock systems and require supervisors to approve any changes made during maintenance work.

Laser Safety Protection Through PPE: Selection, Verification, and Lifecycle Management

Wavelength-Specific OD Calculations and Critical Eyewear Selection Errors

Getting proper eye protection against lasers means doing accurate calculations for Optical Density (OD), which basically measures how much light gets blocked. One big mistake people make is picking glasses that don't match the laser's wavelength. For instance, putting on filters meant for 1064 nm when working with a 532 nm laser cuts down real protection by nearly 90%. And if someone thinks they're getting enough protection but actually needs higher OD ratings, the risks go way up. A Class 4 laser at 500 mW typically needs OD 7 or better, while many Class 3B setups work fine with OD 3 to 5. People often forget about those extra wavelengths some lasers emit or overlook how filter effectiveness changes depending on viewing angle. Checking OD levels regularly with good quality power meters isn't just recommended it's necessary. Recent safety checks in labs showed that almost one third of all protective eyewear wasn't meeting their stated protection standards.

Inspection Protocols and Degradation Thresholds for Laser Eye Protection

Regular checks and proper management throughout the life of safety glasses helps avoid situations where damaged equipment gives people a false sense of protection. Monthly visual inspections are a must, looking out for scratches deeper than half a millimeter, any peeling at the edges, or when those indicator marks start fading away - all signs that the gear needs replacing right away. For quantitative tests on optical density, companies should run these checks every six months with spectrophotometer devices to make sure the protective properties haven't dropped below acceptable levels. Anything falling under 80% of the original OD rating definitely shouldn't stay in circulation anymore. Most makers suggest swapping out eyewear somewhere between two to three years because the materials tend to break down over time. But workers in really busy areas might need to retire their safety glasses sooner than that. Some common signs of wear and tear we've seen documented so far include:

| Degradation Indicator | Action Threshold | Replacement Mandate |

|---|---|---|

| Surface scratches | >3 within central 40mm | Immediate replacement |

| OD performance loss | >20% from baseline | Withdrawal from service |

| Frame flexibility | >15% deformation | Removal within 30 days |

Adherence to these thresholds prevents circulation of degraded PPE—a contributing factor in 28% of academic laser incidents (Laser Institute, 2022).

Administrative and Spatial Safeguards: Establishing Effective Laser Controlled Areas

Laser Controlled Areas, or LCAs, are critical safety zones needed in labs working with Class 3B or Class 4 lasers because these high powered beams can cause serious eye damage or skin burns if someone gets too close without proper protection. These areas combine physical barriers like walls coated with non-reflective materials, doors that lock automatically when the laser is active, and specially designed entry points that block stray beams. Alongside these physical protections come important administrative rules. Labs must post signs according to ANSI Z136 standards, keep records showing staff have completed required training, and set up access control systems managed by designated Laser Safety Officers who make sure only trained personnel enter during operation. Standard work instructions, immediate reporting when something goes wrong, and ways to minimize reflections all help prevent mistakes and accidents. Studies show labs using comprehensive LCA protocols see around 35 percent fewer injuries than places that just rely on basic equipment controls without these additional safety layers.

FAQ

What are the key guidelines for laser safety in research labs?

Guidelines are mainly from ANSI Z136.1 and IEC 60825 standards, categorizing lasers into four risk levels based on their emission limits and safe exposure thresholds.

Why do Class 3B lasers have a high incident rate?

Class 3B lasers have a disproportionate incident rate due to accessibility vs. hazard mismatch, training gaps, and interlock vulnerabilities.

How frequently should safety assessments be conducted for laser hazards?

Safety assessments for potential laser hazards should be conducted formally at least once every year or two.

What factors affect the reliability of engineering controls for lasers?

Reliability of engineering controls can be affected by how well barriers withstand penetration tests, interlock system reliability, and the longevity of materials used for optical components.

How can labs prevent interlock bypass incidents?

Labs can prevent interlock bypass incidents by regular safety training, installing tamper-proof seals on equipment, and incorporating magnetic detectors in lock systems.

What are the recommended inspection intervals for laser eye protection?

Monthly visual inspections are recommended for laser eye protection with quantitative optical density checks every six months.

What are Laser Controlled Areas (LCAs)?

LCAs are designated safety zones in labs using Class 3B or Class 4 lasers, combining physical barriers and administrative rules to prevent accidents from high-powered beams.

Table of Contents

- Understanding Laser Hazard Classification and Risk Prioritization

- Engineering Controls: Design, Validation, and Real-World Reliability

- Laser Safety Protection Through PPE: Selection, Verification, and Lifecycle Management

- Administrative and Spatial Safeguards: Establishing Effective Laser Controlled Areas

-

FAQ

- What are the key guidelines for laser safety in research labs?

- Why do Class 3B lasers have a high incident rate?

- How frequently should safety assessments be conducted for laser hazards?

- What factors affect the reliability of engineering controls for lasers?

- How can labs prevent interlock bypass incidents?

- What are the recommended inspection intervals for laser eye protection?

- What are Laser Controlled Areas (LCAs)?