Laser Classification and Its Direct Impact on Lab Safety Requirements

How Laser Classes 1–4 Define Hazard Levels and Mandatory Controls

Laser classification under ANSI Z136.1 and IEC 60825 standards groups devices into four hazard tiers based on accessible emission limits (AEL), wavelength, and exposure duration—directly determining required safety controls in research labs:

- Class 1 (≤0.39 μW): Fully enclosed systems with no accessible radiation during normal operation. Require only basic lab signage and no user training.

- Class 2 (≤1 mW, visible only): Relies on the human aversion response (blink reflex) for protection. Mandates warning labels and awareness training—especially to discourage intentional staring.

- Class 3R (1–5 mW, visible): Lower power than Class 3B but poses measurable retinal risk from deliberate or sustained viewing. Requires access controls, training, and laser safety eyewear in academic settings.

- Class 3B (5–500 mW): Capable of causing immediate eye injury from direct or specular reflections. Requires interlocked enclosures, beam path containment, OD-rated eyewear, hazard signage, and a designated Laser Safety Officer (LSO) where applicable.

- Class 4 (>500 mW): Presents severe ocular, skin, and fire hazards—even from diffuse reflections. Demands engineered controls (e.g., remote interlocks, emergency shutoffs), strict PPE protocols, controlled access zones, and formal LSO oversight.

This tiered framework ensures safety measures scale proportionally with biological risk—contributing to a 94% reduction in preventable ocular injuries in labs fully compliant with ANSI Z136.1 (OSHA 2023).

Why Class 3R Lasers Pose Unique Risks in Academic Labs Despite Lower Power Ratings

Class 3R lasers tend to show up in most academic incident reports not because they're particularly powerful, but because of where they end up getting used. These lasers cost so little and fit easily into lab setups that they've become standard equipment in teaching environments. Students often handle them directly when setting up experiments, adjusting beam paths, or making last minute tweaks to their optical arrangements. Academic labs differ from industrial settings where everything stays locked down with trained personnel monitoring operations. Instead, classrooms have open beams bouncing around, lots of reflective surfaces like metal tables and glass containers, and varying degrees of adult oversight depending on the day. Many students get complacent too. They'll take off protective glasses for what seems like a quick peek at something or turn off safety interlocks just to demonstrate how things work. According to recent data from 2022, university laboratories saw almost double the number of exposure cases involving Class 3R lasers compared to research departments in companies. Most of these happened during basic optics classes where proper training wasn't provided alongside actual hands-on practice. To reduce risks, schools need to make sure everyone wears appropriate eye protection whenever working with these lasers, track who accesses them through logs, and incorporate real-world safety decisions into regular class activities rather than treating it as another checkbox item on an annual safety seminar.

Key Laser Safety Standards: ANSI Z136.1 and IEC 60825 for Research Labs

Harmonized Principles and Critical Differences Between ANSI Z136.1-2022 and IEC 60825-1:2014

ANSI Z136.1-2022 and IEC 60825-1:2014 share foundational goals: standardized laser classification (Classes 1–4), mandatory risk assessment, and consistent requirements for training and PPE for Class 3B/4 users. Both recognize the Nominal Hazard Zone (NHZ) as central to spatial risk management and require documented control measures for higher-risk lasers.

Key distinctions lie in implementation philosophy and regulatory alignment:

- ANSI Z136.1 emphasizes prescriptive engineering controls—mandating interlocks on Class 3B/4 enclosures and specifying NHZ calculation methods aligned with OSHA workplace safety enforcement.

- IEC 60825-1 adopts a performance-based approach: it permits equivalent safety outcomes through alternative means (e.g., procedural or administrative controls), provided the LSO validates technical justification. It integrates with broader EU frameworks like the Machinery Directive 2006/42/EC rather than occupational health statutes.

For multinational labs, harmonizing these standards requires mapping control strategies to the most stringent requirement per activity—not simply adopting one standard wholesale.

ANSI Z136.5: Specialized Laser Safety Requirements for Educational and Research Laboratories

ANSI Z136.5 fills a critical gap by addressing the dynamic, high-turnover nature of academic labs—where experimental reconfiguration, student-led alignment, and variable expertise elevate exposure risk beyond what Z136.1 alone anticipates. It mandates:

- Institutional LSO approval for all undergraduate and graduate projects involving Class 3R or higher lasers;

- Documented safety training refreshers every six months for graduate researchers and lab staff;

- Enhanced supervision ratios in teaching labs using Class 3R lasers;

- Room access restrictions—including door interlocks or audible alerts—during Class 3B/4 operation;

- Curriculum-integrated safety instruction, not standalone compliance sessions.

Unlike Z136.1’s industrial emphasis on engineering hierarchy, Z136.5 prioritizes administrative rigor and cultural reinforcement—recognizing that in academic labs, the greatest vulnerability lies not in equipment failure, but in procedural drift across shifting user cohorts.

The Laser Safety Officer (LSO): Authority, Duties, and Lab Implementation

When U.S. Academic Labs Are Legally Required to Appoint an LSO

American colleges and universities need to assign someone who knows what they're doing as a Laser Safety Officer (LSO) anytime they're running those powerful Class 3B or 4 lasers around campus. The rules from ANSI Z136.1-2022 and OSHA back this up because even just looking at scattered light from these lasers can cause serious eye damage or skin burns. What makes an LSO different is their official power within the institution to say yes or no to laser work, stop any unsafe practices happening in real time, and make sure everyone follows safety protocols properly. Their job covers things like figuring out where the No Hazard Zone ends, checking if people have the right protective glasses for specific wavelengths, keeping all documentation organized for inspections, and making sure staff members actually understand how to handle lasers safely. According to standard Z136.5, schools also need their LSO to look over and approve any research projects proposed by students that involve these high-powered lasers before letting them anywhere near the lab equipment. Schools that skip appointing or supporting their LSO run the risk of getting fined, facing insurance issues, and showing they didn't take proper care of their students and employees.

Laser Safety PPE: Selection, Verification, and Real-World Use in Labs

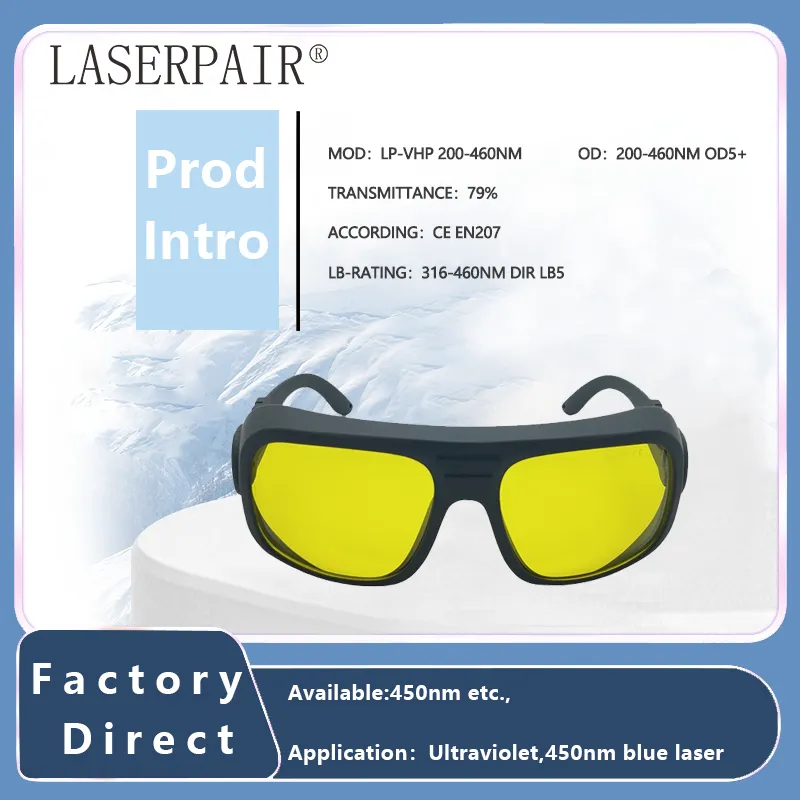

Optical Density (OD) Calculations: Ensuring Eyewear Matches Wavelength, Power, and Exposure Risk

Choosing laser safety glasses isn't just about what the box says or what coworkers swear by. It all comes down to proper Optical Density calculations. What does OD really mean? Well, it measures how much light gets blocked at certain wavelengths. For instance, if something has an OD rating of 6, it cuts down incoming laser power by around one million times (that's 10 to the sixth power). Most people don't realize this, but the right OD level depends heavily on ANSI Z136.1 standards and their Maximum Permissible Exposure limits. These numbers tell us exactly what protection level workers need based on the lasers they're actually dealing with day to day.

Required OD = log₁₀ (Incident Power Density ÷ MPE)

Critical inputs include:

- Exact laser wavelength (e.g., 532 nm vs. 1064 nm);

- Measured or calculated power density (W/cm²) at the eye location;

- Exposure duration and pulse characteristics (CW vs. pulsed).

For example, a 100 mW CW 532 nm laser demands OD ≥4.5 for accidental exposure; the same power at 1064 nm requires OD ≥5.2 due to lower MPE. UV systems (e.g., 266 nm) often require OD 7+—but only if the lens coating is validated for that band.

| Critical OD Selection Factors | Impact on Safety |

|---|---|

| Wavelength mismatch | Zero protection despite high OD rating |

| OD < calculated minimum | Inadequate attenuation—retinal injury possible in <100 ms |

| Damaged or degraded coatings | Compromised filtering, especially after cleaning or impact |

| Miscalculated MPE (e.g., ignoring pulse repetition rate) | Underestimation of true hazard |

Eyewear must be verified annually using calibrated spectroradiometers—and inspected before each use for scratches, delamination, or fit issues. The LSO—not the end user—is responsible for final validation against experiment parameters. Generic “laser glasses” without traceable OD/wavelength certification have no place in compliant labs.

FAQ

Why are laser class distinctions important for lab safety?

Laser class distinctions help determine the safe use of different types of lasers in various research and educational settings. Each class has specific safety measures that reduce the risk of injury and align with ANSI Z136.1 standards, ensuring that lab environments remain safe for users.

Why do Class 3R lasers pose unique risks in academic labs?

Class 3R lasers are often used in academic settings due to their low cost and ease of integration into lab setups. However, the open beams and reflective surfaces present in academic environments, combined with varying levels of supervision, increase the risk of exposure incidents compared to more controlled industrial settings.

What role does a Laser Safety Officer (LSO) play in academic labs?

In academic labs, a Laser Safety Officer (LSO) is responsible for overseeing laser operations, ensuring compliance with safety protocols, and validating the correct safety equipment and eyewear use. Appointing an LSO is mandatory when using Class 3B and 4 lasers, helping prevent accidents and ensuring lab safety.

How is the appropriate Optical Density (OD) for laser safety goggles determined?

The appropriate OD for laser safety goggles is determined using Optical Density calculations, which factor in laser wavelength, power density, and exposure risk based on ANSI Z136.1 standards. The calculations ensure that the eyewear provides sufficient protection against laser exposure.