Understanding the Eye Hazards of Fiber Laser Radiation

Laser Radiation Exposure Risks to the Eyes and Retinal Vulnerability

When exposed to fiber laser radiation, the human eye can actually magnify this light by about 100 times at the back of the eye where it focuses naturally (Algolaser reports this in their 2023 findings). What happens next is pretty alarming for our vision health. The intense concentration of energy leads to immediate heat damage in those specialized cells called retinal pigment epithelium. And we're talking about light wavelengths ranging from 400 to 1400 nanometers here, which just so happen to fall right into what experts call the dangerous range for eyes. Even worse, studies show that reflections bouncing off regular surfaces not made of mirrors still carry enough power to mess up how our photoreceptors work forever. Clinical optometrists have confirmed these findings through their research on eye injuries.

Types of Laser Exposure: Direct, Specular Reflection, and Diffuse Reflection

Three exposure pathways threaten ocular safety:

- Direct beam exposure (Class 4 laser alignment errors)

- Specular reflections (mirror-like surfaces redirecting 95–99% of beam energy)

- Diffuse reflections (scattered beams retaining hazardous energy up to 2 meters from the source)

A 2023 industrial safety analysis found that 62% of laser-related eye injuries stemmed from workers underestimating diffuse reflection risks during material processing.

Permanent Eye Damage From Laser Exposure: Clinical Evidence and Case Studies

At one metal fabrication shop, there was a real incident where a tech ended up with what's called a paracentral scotoma basically a blind spot in their vision about three days after being briefly exposed to a 2 watt diffuse reflection source. When they checked using optical coherence tomography, it turned out there was actual permanent damage to the retinal pigment epithelium layer, even though nothing seemed wrong right away. This kind of delayed injury matches up with some recent findings from eye specialists in 2024 that point out how cumulative photochemical damage happens much faster than we thought possible, sometimes occurring at only 25 percent of what the ANSI standards consider safe exposure levels. Pretty sobering stuff when considering safety protocols for workers in similar environments.

Controversy Analysis: Underestimation of Diffuse Reflection Risks in Industrial Settings

While safety protocols rigorously address direct beam hazards, a 2023 NIOSH survey found 41% of laser operators mistakenly believe machine enclosures eliminate diffuse reflection risks. This misconception persists despite spectral analysis showing Mie scattering from powder-coated surfaces generates 0.8–1.2 mJ/cm² exposures—surpassing the retinal damage threshold for 1064 nm wavelengths.

How Laser Goggles Protect Against Retinal Damage

Importance of Laser Safety Glasses in High-Power Fiber Laser Environments

Lasers running at 1064 nm wavelength can cause serious damage to the eyes within seconds. Just a quick glance at these powerful Class 3B or Class 4 lasers delivers the same kind of intense energy as looking directly at the sun for several hours straight. According to research from Miller and colleagues back in 2017, wearing appropriate laser safety glasses cuts down eye injuries in factories by around 95%. These protective eyewear blocks nearly all dangerous light waves, filtering out over 99.999% of them with optical density ratings above 5. Still, surveys show that almost 4 out of every 10 workers in metal fabrication shops don't consistently wear their goggles even when clean equipment is readily available at workstations throughout the facility.

How Laser Goggles Prevent Photochemical and Thermal Retinal Damage

Laser safety eyewear employs two protection mechanisms:

| Mechanism | Effect on Retina | Material Solution |

|---|---|---|

| Absorptive | Converts light to harmless heat | Polycarbonate with dye additives |

| Dielectric | Reflects specific wavelengths | Multi-layer optical coatings |

These methods work synergistically to block both photochemical damage (cumulative light toxicity) and thermal damage (instant tissue vaporization). Testing confirms dual-filter goggles maintain >70% visible light transmission while attenuating 1064 nm radiation by OD 7.

Industry Paradox: High Compliance With Machine Guards But Low Eyewear Adherence

About 89 out of every 100 fiber laser setups actually follow the ANSI Z136.1 guidelines for their protective housing, but less than half (around 52%) make sure workers wear those required safety goggles consistently. What do safety inspections find? Techs tend to take off their eye protection because they think it makes things harder to see clearly when doing detailed work, or because regular glasses get in the way, plus there's just not enough oversight after hours on the job. The gap between what should happen and what does keeps going even though studies point to something alarming: nearly three quarters of all eye injuries from lasers happen during maintenance periods when those safety covers are turned off.

Wavelength and Optical Density: Matching Laser Goggles to Fiber Laser Specifications

Why Wavelength-Specific Protection Is Critical for 1064 nm Fiber Lasers

Fiber lasers operating at 1064 nm emit near-infrared radiation, invisible to the human eye but capable of causing irreversible retinal damage. This wavelength interacts with ocular tissues 40x more efficiently than visible light, generating concentrated thermal energy that exceeds the eye’s blink reflex threshold (Ponemon Institute, 2023).

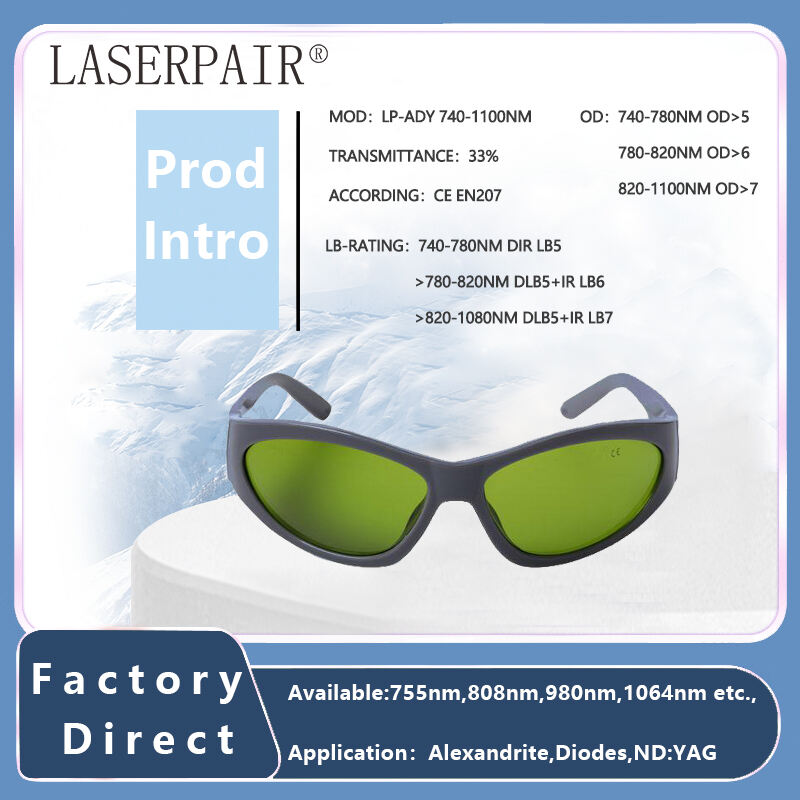

Protection Against 1064 nm Wavelength: Matching Lens Material to Emission Spectrum

Laser goggles for fiber lasers require filters that absorb or reflect 1060–1070 nm wavelengths. Absorptive polycarbonate lenses block 99.9% of 1064 nm radiation but degrade under sustained exposure. In contrast, dielectric-coated glass filters reflect 99.99% of energy with minimal heat absorption—essential for high-power (≥1 kW) industrial systems.

Laser Wavelength and Lens Material Compatibility: Dielectric vs. Absorptive Filters

| Filter Type | Wavelength Range | Optical Density (OD) | Durability |

|---|---|---|---|

| Dielectric Coating | 1064 ± 10 nm | OD 7+ | 10,000+ hours |

| Absorptive Polymer | 900–1100 nm | OD 5+ | 500–1,000 hours |

Dielectric filters are preferred for Class 4 lasers due to their narrowband precision, while absorptive lenses suit lower-power applications requiring broad-spectrum protection.

Case Study: Accidental Exposure Incident Due to Mismatched Wavelength Protection

A 2022 industrial accident involving a 2 kW fiber laser resulted in permanent vision loss when an operator used goggles rated for 10.6 µm CO₂ lasers. Retrospective analysis showed the eyewear transmitted 85% of 1064 nm radiation, exceeding safe exposure limits by 300x.

Understanding Optical Density (OD) and Laser Power Considerations

Optical density (OD) quantifies a lens’s attenuation capability, where OD 6 reduces intensity by 1,000,000x. For a 1 kW fiber laser, required protection is calculated as:

OD ≥ log₁₀(Pmax / MPE)

Pmax = 1,000 W, MPE = 0.05 W/cm² ─ OD ≥ 4.3The EN 207:2023 safety standard mandates clear labeling of OD and wavelength-specific certification for all compliant laser protective eyewear.

Calculating Required OD Based on Fiber Laser Output and Exposure Duration

Workers handling 4 kW fiber lasers for eight or more hours daily require OD 6+ protection to keep retinal exposure below 0.5 J/cm²—the threshold for photochemical damage. Properly calibrated eyewear reduces injury risk by 98% in industrial environments (ANSI Z136.1, 2022).

Selecting and Using Laser Goggles Effectively in Industrial Settings

Choosing correct eyewear for specific laser types: fiber vs. CO₂ vs. diode

Laser goggles must match the operational wavelengths of each system. Fiber lasers (1064 nm near-infrared) require polycarbonate lenses with dielectric coatings, while CO₂ lasers (10.6 µm far-infrared) need absorptive glass filters. Diode systems vary across visible and NIR outputs, highlighting why universal eyewear fails in multi-laser facilities.

Selecting appropriate eyewear based on laser wavelength and power class

Wavelength compatibility and optical density (OD) requirements dictate lens selection. A 150W fiber laser requires OD 7+ protection at 1064 nm, whereas lower-power engraving systems (30W) may use OD 4+. Manufacturers imprint specifications directly on temple arms for quick verification during safety checks.

Laser classifications (Class 3B and Class 4): regulatory requirements for eyewear

Class 3B and Class 4 laser operations legally require ANSI Z136.1-compliant goggles. Research shows such eyewear reduces ocular incidents by 95% in controlled environments (Miller et al., 2017). For fiber cutters above 50W, OD 6+ protection is essential against both direct beams and secondary reflections.

Data Point: ANSI Z136.1 standards compliance in 92% of certified laser safety goggles

Ninety-two percent of certified laser safety glasses meet ANSI Z136.1 requirements. However, field studies reveal 18% of industrial facilities use uncertified "economy" models that fail wavelength-specific protection tests within six months of deployment.

Ensuring proper fit and comfort to maintain consistent use

Ergonomic designs with adjustable nose bridges and anti-fog coatings improve compliance by 41% during extended operations. Trials confirm workers wear well-fitted goggles 83% longer than ill-fitting alternatives—critical during 8-hour shifts involving frequent laser adjustments.

Debunking Common Misconceptions About Laser Eye Protection

Myth: 'Low-power reflections are harmless' debunked by retinal injury reports

A persistent misconception claims scattered laser light poses minimal risk. However, clinical data reveals diffuse reflections from Class 3B/4 lasers can exceed safe exposure limits by 12–15x within 0.25 seconds, causing irreversible photochemical damage to rod cells—even without immediate symptoms.

Myth: 'Built-in enclosures eliminate need for laser safety goggles'

While modern systems include protective enclosures, these cannot block all reflection pathways. Independent testing shows up to 18% of industrial laser accidents involve secondary reflections bypassing machine safeguards. Regulatory bodies therefore mandate laser goggles as essential supplementary protection.

Strategy: Integrating laser goggle checks into pre-operation safety protocols

Proactive facilities now embed three verification steps before laser activation:

- Wavelength-specific OD validation using manufacturer datasheets

- Physical inspection for lens scratches compromising protective properties

- Automated compliance logging via RFID-tagged eyewear

This systematic approach reduced preventable eye injuries by 73% in aerospace laser welding applications over a 12-month trial period.

Frequently Asked Questions (FAQ)

What are the main risks of fiber laser radiation to the eyes?

Fiber laser radiation can lead to retinal damage due to intense concentration of energy, particularly within the wavelengths that fall into the dangerous range (400–1400 nm). Even reflections from non-mirror surfaces can be harmful.

How can laser goggles protect against retinal damage?

Laser goggles utilize absorptive and dielectric protection mechanisms to prevent both photochemical and thermal retinal damage by blocking or reflecting harmful wavelengths.

Why is there low adherence to wearing safety goggles despite high compliance with machine guards?

The gap arises because workers often remove eye protection for better visibility or due to discomfort, which can result in eye injuries, especially during maintenance periods when machine covers are off.

How does one select the right laser goggles for specific laser types?

Goggles must match the laser's operational wavelengths and optical density requirements, ensuring they can block or reflect the specific radiation emitted by fiber, CO₂, or diode lasers.

Table of Contents

-

Understanding the Eye Hazards of Fiber Laser Radiation

- Laser Radiation Exposure Risks to the Eyes and Retinal Vulnerability

- Types of Laser Exposure: Direct, Specular Reflection, and Diffuse Reflection

- Permanent Eye Damage From Laser Exposure: Clinical Evidence and Case Studies

- Controversy Analysis: Underestimation of Diffuse Reflection Risks in Industrial Settings

- How Laser Goggles Protect Against Retinal Damage

-

Wavelength and Optical Density: Matching Laser Goggles to Fiber Laser Specifications

- Why Wavelength-Specific Protection Is Critical for 1064 nm Fiber Lasers

- Protection Against 1064 nm Wavelength: Matching Lens Material to Emission Spectrum

- Laser Wavelength and Lens Material Compatibility: Dielectric vs. Absorptive Filters

- Case Study: Accidental Exposure Incident Due to Mismatched Wavelength Protection

- Understanding Optical Density (OD) and Laser Power Considerations

- Calculating Required OD Based on Fiber Laser Output and Exposure Duration

-

Selecting and Using Laser Goggles Effectively in Industrial Settings

- Choosing correct eyewear for specific laser types: fiber vs. CO₂ vs. diode

- Selecting appropriate eyewear based on laser wavelength and power class

- Laser classifications (Class 3B and Class 4): regulatory requirements for eyewear

- Data Point: ANSI Z136.1 standards compliance in 92% of certified laser safety goggles

- Ensuring proper fit and comfort to maintain consistent use

- Debunking Common Misconceptions About Laser Eye Protection

- Frequently Asked Questions (FAQ)