Understanding the Eye Hazards of Fiber Laser Exposure

Direct Eye Exposure to Fiber Laser Beams and Retinal Damage

Fiber lasers can boost light energy by as much as 100 thousand times using how our eyes naturally focus things. When this intense beam hits the back of the eye, it creates heat fast enough to damage those pigment layers in the retina almost instantly. What happens next is pretty bad for anyone who looks at it directly the photoreceptor cells get cooked and stop working properly. People working around these industrial lasers, especially ones emitting that 1064 nm wavelength which is super common in manufacturing settings, are really at risk. We've seen cases where workers ended up with macular holes or lost their central vision completely after just brief exposure incidents.

Invisible Infrared Radiation: A Silent Hazard

Over 60% of fiber laser injuries stem from undetected infrared emissions (1030—1080 nm range). These wavelengths bypass the blink reflex, allowing hazardous radiation to reach the retina before discomfort is sensed. A 2023 study found that 78% of cases had delayed symptom onset, with blurred vision and photophobia appearing hours after exposure.

Reflected Laser Light Hazards in Industrial Environments

Secondary exposure pathways include metal surface reflections (retaining up to 40% beam intensity), scattered light from vaporized materials, and diffuse reflections from matte surfaces. Even indirect exposure can deliver intensities exceeding 50 mW/cm²—12 times the ANSI safe limit for Class 4 lasers—posing serious ocular risks.

Permanent Eye Damage from Unprotected Exposure: Case Studies

Industrial injury reports highlight real-world consequences:

- Case 1: Technician developed a retinal scar after 0.25-second exposure to a reflected 2kW beam

- Case 2: Operator sustained bilateral macular damage despite no direct beam contact

- Case 3: Maintenance worker incurred cataracts following six months of subthreshold exposures

Recent analyses confirm that 93% of occupational laser injuries involved improper eyewear use, underscoring the critical need for wavelength-specific protection.

How Laser Goggles Protect Against Harmful Wavelengths

Importance of Laser Goggles for Eye Protection in High-Power Settings

Laser safety glasses are absolutely necessary when working around powerful industrial lasers. Just think about this: even a brief flash from a 1 kW fiber laser packs 100 times the energy needed to seriously harm the human eye. The right protective eyewear functions as these amazing filters that stop nearly all dangerous radiation, usually made from tough materials such as polycarbonate or special types of glass. For real world applications, many professionals opt for industrial strength versions equipped with anti-fog treatments so they can see clearly without compromising their vision protection. These devices effectively shield workers from those specific 1064 nm wavelengths commonly found in cutting operations involving metals across manufacturing facilities everywhere.

How Laser Safety Goggles Block Harmful Wavelengths Effectively

Laser safety goggles make use of special dielectric coatings along with dye based filters that either absorb or bounce back certain wavelengths of light. The whole point is to stop those harmful invisible infrared rays between 900 and 1100 nanometers from getting anywhere near the eyes. Regular old safety glasses just don't cut it here. Properly certified laser goggles go through rigorous spectral tests so they can block more than 99 percent of whatever wavelength they're designed for, yet still let around 80% of regular visible light pass through. This balance makes sure workers can see what they're doing without compromising their eye safety in the process.

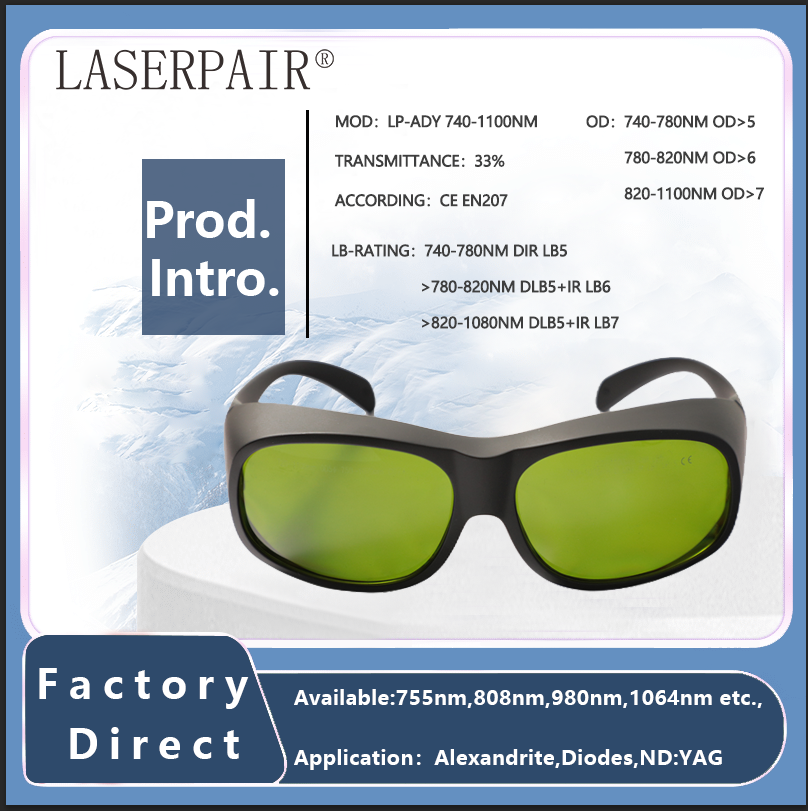

Optical Density (OD) and Laser Power: Matching Protection to Output

Selecting goggles with the correct optical density (OD) is crucial—a difference of just one OD unit allows ten times more laser energy transmission. The table below outlines key requirements:

| Laser Power | Minimum Required OD | Protection Duration |

|---|---|---|

| ≥1W | OD 3+ | Full-shift operations |

| 5—50W | OD 5+ | Heavy cutting tasks |

| 100W+ | OD 7+ | Aerospace welding |

Always verify goggle OD ratings at your laser’s exact wavelength, as performance varies across the spectrum. Manufacturers provide OD/wavelength charts compliant with ANSI Z136.1 standards to guide proper selection.

Wavelength-Specific Protection: Choosing the Right Laser Goggles

Protecting your vision from fiber laser hazards requires precision-matched eyewear based on operational wavelength, optical density needs, and lens material compatibility. Generic safety glasses cannot offer adequate defense; effective protection must align with both the laser’s frequency and power level.

Wavelength and Optical Density Requirements for Laser Protection

Safety goggles for lasers function through selective absorption of certain light wavelengths. Optical density, or OD rating, basically tells us how well these goggles block out harmful light. For instance, an OD rating of 6 means the goggles cut down on transmitted light by around one million times. When dealing with those powerful industrial fiber lasers that operate at 1064 nanometers, most experts recommend going for OD ratings above 7. But don't worry about spending extra bucks if working with smaller alignment lasers since they generally get away with just OD 4 protection. Just remember to check what kind of laser we're talking about here. Make sure the goggles are rated for both the maximum power output and exact wavelength of whatever laser equipment is being used. Getting this wrong can lead to serious eye damage despite wearing protective gear.

Laser Wavelength and Lens Material Compatibility: Ensuring Full Blocking

Materials like coated glass and polycarbonate infused with dyes have been specifically designed to block certain wavelengths of light. Take neodymium-doped glass for instance it works really well at absorbing that 1064 nm infrared stuff we see coming from fiber lasers all the time. Then there's amber tinted polycarbonate which gives good coverage against both visible green light around 532 nm mark and also protects from nearby infrared frequencies. When dealing with systems that handle multiple wavelengths, many manufacturers turn to composite lenses or stack different layers together. This approach stops harmful light from getting through where it shouldn't be going.

Fiber Laser Safety Glasses Tailored to 1064 nm and Other Common Wavelengths

Around 78 percent of injuries from industrial fiber lasers happen when workers are exposed to 1064 nm wavelengths, which makes proper eye protection absolutely essential. Safety glasses designed for fiber lasers typically offer optical density (OD) ratings above 7 at 1064 nm while also protecting against other wavelengths that might be present, such as the 532 nm harmonics. When dealing with CO2 lasers that operate at much longer wavelengths around 10,600 nm, special lenses made from zinc selenide material block those harmful infrared rays effectively. What's great about these lenses is they don't fog up or distort vision, so operators can maintain clear sight lines even when doing detailed work like engraving or making precise cuts.

Compliance with Industrial Safety Standards for Laser Use

Use of Laser Goggles in industrial settings: OSHA and ANSI guidelines

Safety protocols for industrial lasers are governed by pretty strict regulations across the board. The ANSI Z136.1 standard sets specific requirements for optical density based on different wavelengths, plus makes sure there's proper shielding from those pesky diffuse reflections we all know about. Over here in the US, OSHA backs up these rules through their 29 CFR 1910 guidelines, working hand in hand with ANSI when dealing with really dangerous laser operations. Looking globally, the IEC 60825-1 standard offers similar protections, though it also throws in mandatory yearly checks of equipment and keeps records of worker training sessions. Some recent numbers from 2023 indicate around a 70 something percent drop in accidents involving lasers once companies started wearing ANSI approved protective glasses and following consistent safety routines throughout their facilities.

Fiber lasers and safety considerations in manufacturing workflows

When bringing fiber lasers into manufacturing workflows, specific safety protections become absolutely necessary. The engineering side needs things like proper beam enclosures and interlock systems working hand in hand with personal protective equipment, particularly important when dealing with those 1064 nm wavelength systems common in material processing applications. Regular checks on how everything lines up can stop dangerous reflections from happening accidentally, and doing risk assessments tailored to each particular task helps keep workers safe during maintenance periods. For shops running Class 4 lasers, establishing a strict "safety pause" procedure right before turning on high power levels makes good sense. Real time monitoring of emissions adds another layer of protection here. According to Occupational Health Analytics from last year, around one out of every five laser injuries happens because someone skipped or messed up some basic safety step in busy factory settings where things move quickly.

FAQ

What are the potential eye hazards of fiber lasers?

Fiber lasers can amplify light energy significantly, which can cause retinal damage and central vision loss through direct or indirect exposure.

Why are infrared emissions from fiber lasers dangerous?

Infrared emissions are often undetected by the blink reflex, meaning they can reach the retina and cause damage without immediate discomfort.

How do laser safety goggles protect against fiber laser hazards?

Laser safety goggles are designed with special coatings to block harmful wavelengths and protect the eyes from both direct and reflected laser light.

What is the role of Optical Density (OD) in laser safety goggles?

OD measures how well goggles can block laser light; selecting the correct OD ensures adequate protection against the specific power and wavelength of the laser.

Are generic safety glasses sufficient for fiber laser protection?

No, generic safety glasses do not offer the specific wavelength and power level protection required for fiber laser operations.

Table of Contents

- Understanding the Eye Hazards of Fiber Laser Exposure

- How Laser Goggles Protect Against Harmful Wavelengths

- Wavelength-Specific Protection: Choosing the Right Laser Goggles

- Compliance with Industrial Safety Standards for Laser Use

-

FAQ

- What are the potential eye hazards of fiber lasers?

- Why are infrared emissions from fiber lasers dangerous?

- How do laser safety goggles protect against fiber laser hazards?

- What is the role of Optical Density (OD) in laser safety goggles?

- Are generic safety glasses sufficient for fiber laser protection?