Understanding Laser Wavelengths and Protection Requirements

The Role of Laser Wavelength in Safety Design

For laser protection screens to work properly, they need to match exactly with the wavelength being used during operations. When dealing with UV lasers between 200 and 400 nanometers, special materials like coated glass are necessary to stop those powerful photons from getting through. On the other hand, IR lasers ranging from 700 nm all the way up to 1 millimeter call for different approaches entirely, typically requiring screens that can handle heat without breaking down. Research published last year in the Laser Safety Journal showed something pretty alarming actually – when protective gear doesn't match the laser's wavelength correctly, workers face a 63% higher chance of getting injured. This really highlights why following ANSI Z136 guidelines matters so much for anyone working with these kinds of equipment day to day.

How Protection Needs Vary Across UV, Visible, and IR Laser Applications

- UV Lasers (200–400 nm): Require screens with OD 5+ at 355 nm to prevent retinal burns and material degradation

- Visible Spectrum (400–700 nm): Neutral-density filters with broadband absorption reduce glare while maintaining visibility

- IR Lasers (1064 nm common): Polycarbonate screens with heat-dissipative coatings help prevent thermal warping

Critical material properties—such as transmittance ≤0.1% at target wavelengths—distinguish compliant from inadequate protection solutions.

Why Universal Laser Protection Screens Are Ineffective Across Spectra

Single material solutions just don't work when optical density changes so much across different wavelengths. Take acrylic screens for instance they might block about 90% of that 532 nm green laser light, yet still let through around 40% of the 1064 nm infrared radiation. What happens next? Well, this creates problems with safety standards. Looking at recent EN 207 audits from last year, nearly four out of five facilities that relied on these so called universal screens ended up exceeding their Maximum Permissible Exposure limits when multiple lasers were in operation. Makes sense why many manufacturers are now reconsidering their screen choices altogether.

Optical Density and Wavelength-Specific Attenuation Performance

Defining Optical Density (OD): The Core Metric for Laser Safety

Optical Density, or OD for short, basically tells us how good a material is at blocking laser light. The formula goes something like this: OD equals negative log base ten of T, with T standing for transmittance. Most people don't need to remember the math though. What matters practically is that an OD rating of 6 means the screen stops almost all the light coming through it, specifically 99.9999%. That kind of protection level is what workers need when dealing with those powerful Class 4 industrial lasers we see in manufacturing settings. Regular tinting just doesn't cut it here because optical density works on a logarithmic scale. Every time the number goes up by one point, the protection jumps tenfold. This makes OD ratings the go to measure for safety standards set out in ANSI Z136.1-2022 guidelines. Manufacturers have been relying on this system for years now.

Measuring Attenuation Across Laser Protection Screen Materials by Wavelength

Material performance varies significantly across the spectrum:

| Material | UV (200–400 nm) OD | IR (1064 nm) OD |

|---|---|---|

| Polycarbonate | 4.2 | 1.8 |

| Coated Glass | 6.5 | 5.1 |

| Dyed Acrylic | 3.1 | 3.9 |

| Data from 2023 Laser Safety Institute materials testing |

Coated glass offers superior UV and IR attenuation, while polycarbonate performs well in UV-C applications but is less effective in mid-IR bands.

How OD Ratings Guide Protective Efficacy for Specific Laser Bands

The optical density requirements really come down to two main factors: laser power levels and how long someone is exposed. Take a standard 5 watt green laser operating at 532 nanometers as an example. For quick glances lasting under quarter of a second, OD rating 3 or higher works just fine. But when working with these lasers continuously, safety glasses need to be rated at least OD 7. According to findings presented at last year's Photonics Safety Symposium, carbon dioxide lasers at 10.6 microns wavelength typically need OD 4 protection for eye safety, especially around the cornea area. Interestingly enough, the same power level at 1550 nm wavelength actually requires much less protection, just OD 2 because our eyes absorb light at that wavelength far less effectively.

Case Study: Comparing OD Performance in UV vs. IR Laser Environments

In semiconductor lithography (355 nm UV), coated glass screens achieved OD 6.2 with <0.1% transmittance after 800 hours of testing. The same material delivered OD 4.7 at 2 µm IR in laser welding setups due to molecular resonance limitations. This 27% drop in performance highlights why ANSI Z136.1-2022 mandates wavelength-specific certification for all protective screens.

Materials Used in Laser Protection Screens and Their Spectral Performance

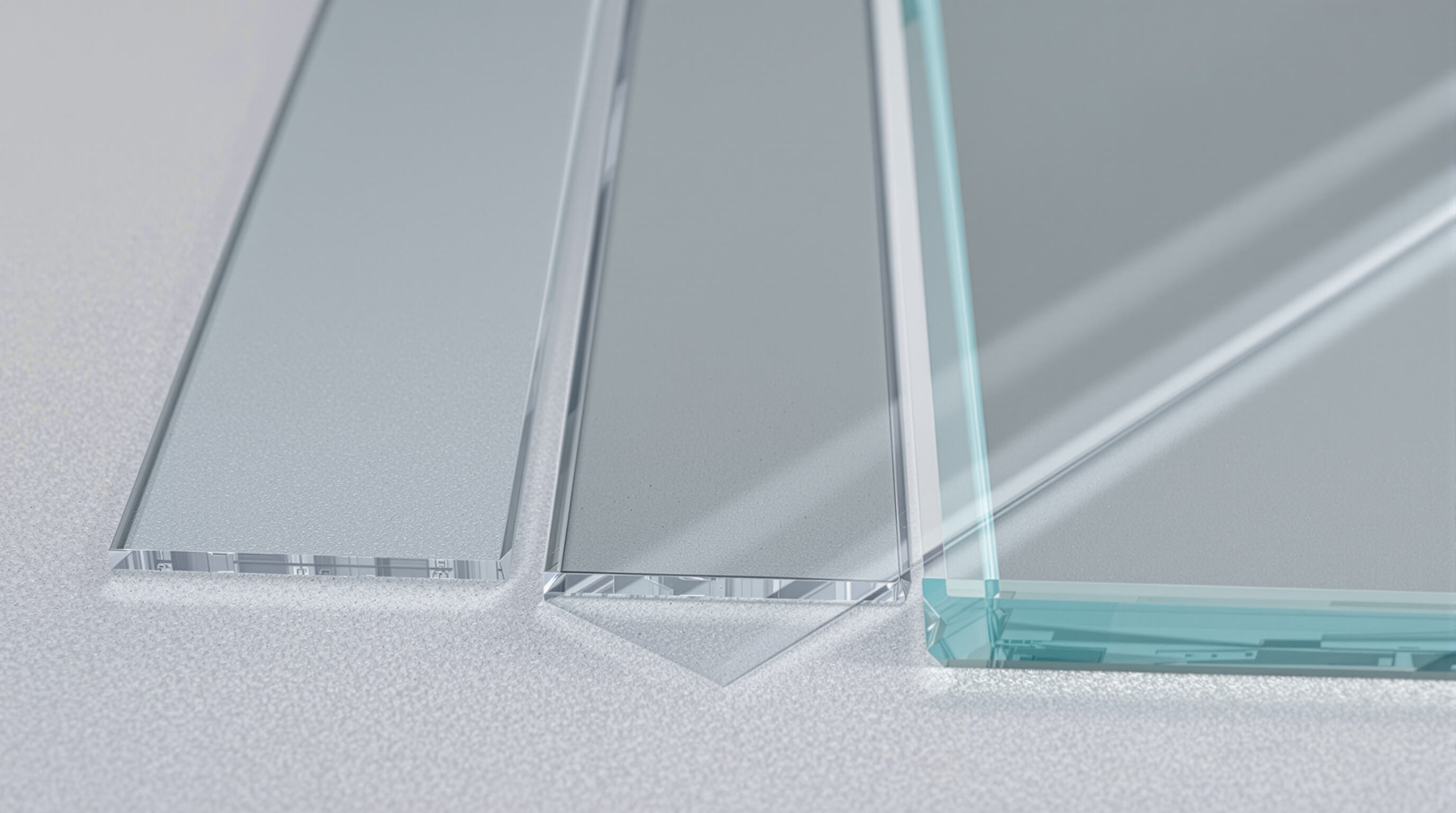

Polycarbonate, Acrylic, and Coated Glass: Common Materials Compared

Materials designed to protect against lasers need to be pretty precise when it comes to different wavelengths of light. Take polycarbonate for instance PC material can take a beating thanks to its impact resistance properties. It also soaks up around 98 percent of those harmful UV-C rays between 200 and 280 nanometers while still letting through about 89% of visible light. Acrylic or PMMA works well too at blocking out UV-A and B radiation from 315 to 400 nm range. However, acrylic tends to crack easily which makes it less suitable for dealing with powerful infrared lasers. Glass coated with special dielectric layers can handle very narrow bands of infrared light achieving optical density ratings above 6. But let's face it nobody wants to carry around heavy fragile glass shields all day long. Independent tests have actually shown that polycarbonate keeps performing reliably even when exposed to multiple wavelengths over time. After sitting under 1064 nm Nd:YAG laser beams for 5,000 straight hours, the material only degraded by less than 0.1%, making it a solid choice for many industrial applications where durability matters most.

Transmittance, Durability, and Multi-Wavelength Compatibility

| Material | UV (200-400 nm) OD | Visible (400-700 nm) OD | IR (700-1500 nm) OD | Impact Resistance (J/m²) |

|---|---|---|---|---|

| Polycarbonate | 3.5 | 1.2 | 2.8 | 120 |

| Acrylic | 4.1 | 0.9 | 1.4 | 45 |

| Coated Glass | 5.9 | 4.3 | 6.2 | 18 |

Acrylic’s poor IR attenuation restricts its use in fiber laser systems, while polycarbonate’s balanced profile supports mixed-wavelength settings like medical diode laser suites.

Advancements in Nanocoated Substrates for Broadband Laser Protection

The latest nanocoated polymer films can reach optical density of 4+ throughout the wavelength range from 200 to 1500 nm by layering metal oxides and polymers alternately at the nanoscale. The coating thickness ranges between 50 and 200 micrometers, and these materials have interesting properties - they bounce back green laser light at 532 nm wavelengths but simultaneously soak up CO2 emissions at 10.6 microns. Tests done by third parties show these new coatings reduce thermal warping problems by around two thirds when compared with conventional coated glass that offers similar optical density. This makes them particularly suitable for use in factories and other settings where temperature fluctuations are common and equipment needs to maintain stability over time.

Selecting the Right Material Based on Operational Wavelength Requirements

Match material properties to laser specifications:

- UV excimer lasers (248 nm): Use coated glass (OD ≥5) with anti-ablation surface treatments

- Mixed visible/IR surgical lasers: Choose nanocoated polycarbonate (OD 3.5–4.2) for balanced visibility and protection

- High-power IR industrial lasers: Prioritize coated glass or hybrid screens with cooling layers

ANSI Z136 standards require annual wavelength-specific OD validation, as material degradation in high-humidity conditions can reduce attenuation by 0.3–0.7 OD per year.

Reflective vs. Absorptive Technologies in Laser Protection Screens

Reflective Filters: Managing High-Intensity Laser Exposure Safely

Dielectric coated reflective screens manage to bounce back around 95 to nearly all of the incoming laser energy away from people working nearby according to LIA research from last year. These screens work really well against those short burst IR lasers we commonly see at wavelengths like 1064 nm, which can pack an intense punch of over 10 million watts per square centimeter during those brief nanosecond pulses. The catch though is that because these screens have specific angles built into them, they need to be installed just right so no dangerous reflections escape. Some testing done in 2022 showed something interesting too. When these high quality OD 7 plus screens were placed more than 15 degrees off the actual beam line, they still kept diffuse reflections below 0.01 percent throughout the whole 700 to 1100 nm range.

Absorptive Technologies: Heat Dissipation and Long-Term Stability

Absorptive screens convert laser energy into heat via doped polymers and nanoceramic layers. Advanced gradient-index polycarbonate composites sustain OD 5 performance at 532 nm for over 5,000 hours. Under continuous 100W IR exposure, conductive cooling channels limit surface temperature rise to under 3°C (Journal of Laser Applications, 2023).

Key Performance Comparison:

| Parameter | Reflective Screens | Absorptive Screens |

|---|---|---|

| Thermal Management | Passive (ambient air) | Active (cooling systems) |

| OD Stability | ±0.1 OD over 10 yrs | -0.3 OD/yr (UV degrade) |

| Optimal Wavelength | 780-1550nm (NIR) | 190-550nm (UV-Visible) |

Trade-offs Between Reflection and Absorption in Shared Workspaces

Manufacturing facilities that run YAG cutting lasers at 1064 nm wavelength alongside UV marking systems operating at 355 nm wavelengths often find hybrid setup configurations work best for their operations. According to ANSI Z136.7 guidelines, there needs to be a minimum distance of 1.2 meters between the reflective infrared screens used for laser cutting and the absorptive barriers required for UV marking applications. Practical testing in real world environments has demonstrated that when shops combine OD 6 reflective panels angled at 45 degrees with OD 4 plus absorptive materials, they see around an 83 percent reduction in cross station glare issues compared to facilities that stick with only one type of shielding technology throughout their workspace.

The Risk of Thermal Damage in High-OD Reflective Screens

Copper based reflective coatings can reach OD 10+ at 10.6 microns for CO2 lasers, but they tend to break down completely when temperatures hit around 650 degrees Celsius. That's pretty quick too - sometimes within just over a minute when exposed to 400 watt focused beams. Looking back at incidents from 2022 shows most problems happened during those intense fiber laser operations where heat buildup went past 2 kilowatt minutes per square meter. The good news is there's a way to cut down on this risk. Industry experts recommend combining these protective screens with infrared thermal sensors. These sensors will automatically shut off the laser beam once it reaches 400 degrees, giving operators some much needed safety margin before things start going wrong.

Laser Safety Standards and Compliance for Wavelength-Specific Protection

Overview of ANSI Z136 and EN 207 Standards for Laser Protection Screens

Laser safety standards come primarily from two major organizations: ANSI Z136 in America and EN 207 across Europe. These standards form the backbone of how industries handle lasers safely. The ANSI Z136 standard covers pretty much every industry where lasers are used, laying out exactly what kind of protective measures need to be in place. For instance, it specifies different types of laser protection screens depending on whether we're dealing with Class 3B or Class 4 lasers and what kind of work environment they're being used in. Meanwhile, EN 207 takes a different approach by requiring specific tests for optical density when it comes to both eye protection gear and those same protective screens. This ensures that whatever light gets through is properly filtered according to its wavelength. Both sets of guidelines tackle the obvious dangers from direct laser beams, which can cause serious retinal damage, but also don't forget about other potential problems like electrical hazards that might occur during normal operation.

How Standards Define Wavelength-Specific OD Requirements and Testing

The connection between optical density (OD) ratings and specific wavelengths is established through various standards. Take EN 207 as an example it mandates an OD of 7 or higher at 1064 nm when dealing with infrared protection. On the other hand, ultraviolet applications around 355 nm need special materials that absorb light effectively at those particular wavelengths. When it comes to compliance testing, manufacturers expose protective screens to calibrated laser sources covering the entire spectrum from 190 to 1500 nm. They then measure how much energy actually passes through these screens to check if they block enough light as claimed. Meeting this requirement means achieving that impressive 99.999% blocking rate at the stated OD level, which becomes absolutely essential when working with dangerous Class 4 lasers commonly found in industrial environments where eye safety is paramount.

Aligning Laser Protection Screen Selection with International Safety Certification

To ensure compliance, verify two key criteria:

- Wavelength-specific certification: Look for markings like “D L4 1064 nm OD 7+” (EN 207) or “ANSI Z136 OD 6 @ 532 nm”

- Third-party validation: Independent labs such as TÜV Rheinland or UL conduct testing under IEC 60825-1 to confirm performance

Manufacturers using certified products reduce liability risks by 74% compared to those relying on uncertified alternatives (Laser Safety Journal, 2022). Always align screen specifications with the laser’s emission spectrum and local exposure limits.

FAQs about Laser Wavelengths and Protection Requirements

What is optical density (OD) and why is it important?

Optical Density (OD) measures how effectively a material can block laser light. It uses a logarithmic scale where each unit increase results in tenfold increased protection, critical for laser safety standards.

Why are wavelength-specific screens necessary for laser protection?

Wavelength-specific screens ensure maximal protection by blocking laser wavelengths effectively. Mismatched screens can lead to higher injury risks due to insufficient blockage.

What are the common materials used in laser protection screens?

Polycarbonate, acrylic, and coated glass are commonly used materials. Each has specific OD performance characteristics suitable for different laser types ranging from UV to IR spectrums.

How do reflective and absorptive technologies differ in laser screens?

Reflective screens bounce back laser energy, ideal for NIR wavelengths, while absorptive screens convert it into heat, suitable for UV and visible ranges, each offering unique benefits and drawbacks.

What is the role of standards like ANSI Z136 and EN 207?

These standards provide guidelines for laser safety, ensuring protective measures are in place by defining OD requirements based on laser types and use environments to prevent injuries.

Table of Contents

- Understanding Laser Wavelengths and Protection Requirements

- Optical Density and Wavelength-Specific Attenuation Performance

- Materials Used in Laser Protection Screens and Their Spectral Performance

- Reflective vs. Absorptive Technologies in Laser Protection Screens

- Laser Safety Standards and Compliance for Wavelength-Specific Protection

-

FAQs about Laser Wavelengths and Protection Requirements

- What is optical density (OD) and why is it important?

- Why are wavelength-specific screens necessary for laser protection?

- What are the common materials used in laser protection screens?

- How do reflective and absorptive technologies differ in laser screens?

- What is the role of standards like ANSI Z136 and EN 207?