Match Laser Classification to Required Safety Product Specifications

Decoding Laser Classes 1–4 and Subclasses (1M, 2M, 3R, 3B, 4) and Their Direct Implications for Laser Safety Products

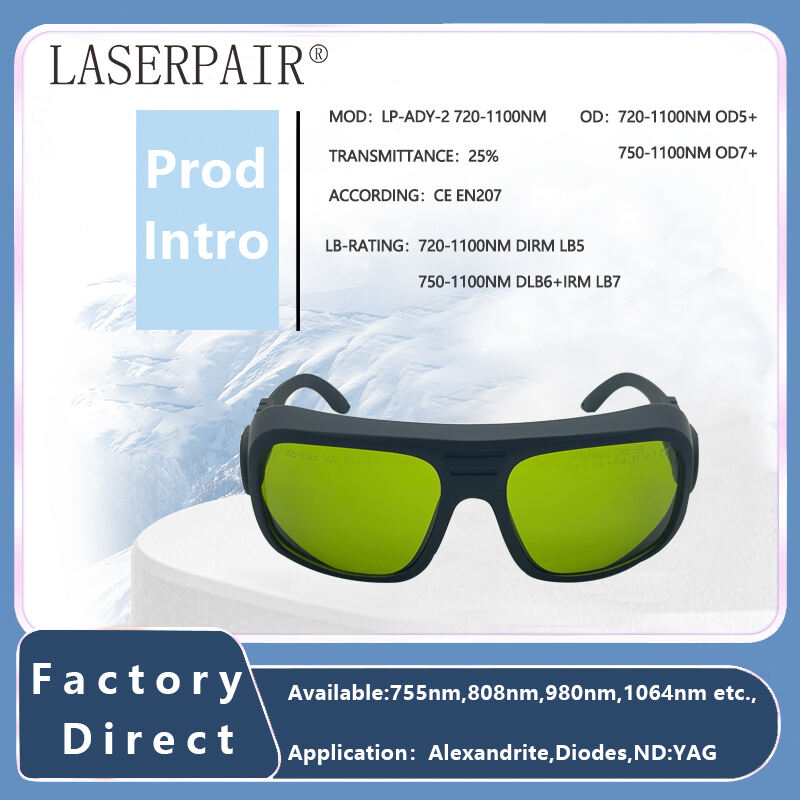

The classification system for lasers basically tells us how dangerous they are and what kind of safety measures we need to put in place. Class 1 lasers aren't really a threat when used normally and generally don't need any special protection gear. With Class 2 lasers, which work within visible light ranges up to 1 milliwatt, our natural blink reflex usually protects us. Still, people might need to wear eye protection if they stare at them for long periods or during alignment work. Things get trickier with subclasses 1M and 2M because looking through things like microscopes or telescopes can turn what seems safe into something dangerous. That's why these setups often need specific filters tailored to the laser's wavelength. Moving up to Class 3R lasers between 1 and 5 milliwatts, we start needing proper access control, warning signs, and written rules about eye protection even though short exposures aren't super risky. Then there are the real troublemakers: Class 3B lasers ranging from 5 to 500 milliwatts and Class 4 ones above 500 milliwatts. These bad boys can cause serious harm like skin burns and permanent eye damage from both direct hits and reflections. Safety for these means locked enclosures, strict operating procedures, and specially designed laser goggles that block exactly the right amount of light based on the laser's wavelength. Take a typical industrial Nd:YAG laser working at 1064 nanometers for instance. Workers need goggles rated at least OD 5 for that wavelength along with beam stops, emergency shut off switches, and restricted areas where only trained personnel can operate the equipment.

Translating Hazard Characteristics (e.g., CW vs. pulsed, wavelength, power) into Minimum Qualification Criteria for Laser Safety Products

When it comes to laser safety, product specs need to cover much more than basic classification. Continuous wave lasers create ongoing heat issues, so protective gear has to handle constant exposure levels. For pulsed lasers, particularly ones firing nanosecond or picosecond bursts, safety equipment must pass specific tests under IEC 60825-1 standards. Even when average power seems low, those brief but intense pulses can damage filters or crack lenses over time. The wavelength matters too because protection needs to work across all emitted light ranges. That means covering not only the main beam but also secondary outputs like harmonics (think about how a 1064 nm laser might produce 532 nm light) plus any unexpected broad spectrum emissions that come along for the ride. Don't forget power density calculations either. A 150 watt CO2 laser operating at 10.6 microns requires way more optical density protection compared to a small 5 watt diode at 635 nm simply because of how concentrated its energy is. Real world laser safety gear should specify exactly what wavelengths they block, confirm their ability to withstand actual pulse conditions, and maintain structural integrity during regular operations beyond just meeting minimum class requirements.

Confirm Compliance with Globally Recognized Laser Safety Standards

ANSI Z136.1 and IEC 60825-1: Critical Differences in Certification Requirements for Laser Safety Products

The ANSI Z136.1 standard from the United States works alongside the international IEC 60825-1 standard for laser safety, though each has its own specific focus area. ANSI Z136.1 deals mainly with the organizational aspects of laser safety programs. It requires companies to appoint a Laser Safety Officer, conduct thorough risk assessments, implement proper training procedures, and establish clear operational guidelines. On the other hand, IEC 60825-1 looks at safety from the product perspective. This standard sets out maximum emission levels, explains how lasers should be classified, and specifies necessary physical protections like key locks, delayed emissions, and secure enclosures. Although both standards contribute to laser safety certification, their approaches are quite different. ANSI essentially verifies safe usage practices, whereas IEC checks whether lasers themselves have been designed with built-in safety features. When deploying lasers internationally, following both standards makes good sense. It's not just extra work but actually creates better protection by combining proper workplace procedures (covered by ANSI) with reliable equipment design (addressed by IEC). Choosing products that meet the relevant local standard helps avoid legal problems and keeps operations running smoothly across different countries.

BS EN 207/208 Eyewear Standards: Why Optical Density (OD), Wavelength Coverage, and Pulse Durability Define Qualified Laser Safety Products

In Europe, BS EN 207 covers direct beam protection while EN 208 deals with alignment work, setting the standard requirements for laser safety glasses across the continent. There are three key factors that cannot be ignored when looking at protective eyewear specs: Optical Density (OD), wavelength range, and how well the material holds up against pulses. The OD number tells us how much light gets blocked out. For instance, an OD rating of 6 means it cuts down on incoming light by about 99.9999%. Important thing here is that this OD value needs to be stated specifically for each wavelength the glasses will encounter, not just an average figure across multiple wavelengths. When it comes to covering different wavelengths, manufacturers need to account for everything emitted by lasers including main beams, harmonic frequencies, and those unexpected side outputs too. A product marked as good for 1064nm but missing coverage at 532nm won't pass EN 207 standards when someone tries to use it with systems that double their frequency output. Testing for pulse resistance follows EN 207 guidelines which categorize materials based on D (nanoseconds), R (microseconds), I (milliseconds), or M (continuous wave) ratings. These tests check whether filters can handle intense bursts without breaking apart, developing cracks, or letting through sudden surges of light. Any gear that meets all these standards goes through independent checks with actual laser equipment set up to mimic real world usage scenarios. What really sets proper safety eyewear apart isn't just having labels that say "compliant" but going through thorough tests tailored to specific applications instead of generic claims.

Validate Real-World Performance Through Risk-Based Evaluation

From MPE Calculation to NHZ Mapping: How Hazard Assessment Drives Selection of Qualified Laser Safety Products

Getting the right laser safety gear means going past just checking labels to actually assess risks specific to each workplace situation. The whole thing starts with figuring out what's called Maximum Permissible Exposure or MPE. Basically, this tells us the maximum amount of radiation that won't hurt people depending on factors like color of light, how long someone might be exposed, and whether it comes in short bursts or continuous waves. These MPE numbers form the foundation for everything else in safety planning. They help decide what kind of eye protection workers need, where barriers should go, and how far away from lasers people must stay. Then there's something called Nominal Hazard Zone mapping which shows exactly where beams become unsafe because they exceed these MPE limits. This takes into account things like reflections off surfaces, how much the beam spreads out as it travels, and whether equipment enclosures are properly sealed. When companies combine their MPE calculations with NHZ maps, they can put protective measures exactly where needed. For instance, putting permanent barriers along the edges of hazard zones makes sense, while maybe only requiring special glasses rated OD 7 within two meters of certain high power lasers. This approach stops situations where safety measures are either too weak or way overkill. Shops that switched to this comprehensive method saw about 37 fewer accidents involving lasers than places still buying gear based purely on manufacturer classifications. That's according to recent data presented at last year's International Laser Safety Conference.

Assess Engineering Controls and PPE Integration for Operational Safety

Good laser safety depends on multiple layers of protection. The best approach starts by eliminating dangers at their source, then deals with what's left using proper personal protective gear that has been tested and verified. Engineering controls like interlocked enclosures, beam shutters, remote stations where operators can fire lasers safely, and systems to pull away harmful fumes all tackle risks right at the design stage, which means we don't have to rely so much on people always doing things perfectly. But there are times when even these engineered solutions fall short, especially during routine maintenance work, when aligning components, or when technicians need to check beams directly. That's when certified PPE steps in as our final safeguard against accidents. Safety protocols generally follow this order: fix problems through engineering first, implement administrative rules next, and only then turn to PPE as backup, not replacement. When choosing PPE, context matters a lot. For instance, eye protection needs optical density ratings higher than the maximum permissible exposure level at each specific work location, while barriers should handle whatever intensity and pulse patterns might occur. We also need to keep checking everything regularly, especially after upgrading lasers, changing procedures, or reviewing incidents. These checks make sure our safety measures stay aligned with how operations actually change over time. With this kind of thoughtful approach, safety stops being just about following rules and becomes something active and responsive to real conditions on the job site.

FAQ

- What are laser classes and their importance? Laser classes indicate the level of hazard associated with different lasers, guiding what safety measures need to be implemented to prevent harm.

- Why do laser safety product specifications vary? The specifications vary because they must address various factors including laser class, power density, wavelength, and whether the laser operates continuously or in pulses.

- What's the difference between ANSI Z136.1 and IEC 60825-1? ANSI Z136.1 focuses on organizational aspects of laser safety programs, while IEC 60825-1 deals with safety from the product design perspective, setting emission level limits and laser classification criteria.

- Why is Optical Density important for laser safety glasses? Optical Density (OD) refers to how much light a laser safety glass can block and is crucial for ensuring that eyewear effectively prevents eye damage.

- How do MPE calculations impact laser safety? Maximum Permissible Exposure calculations are used to determine safe exposure levels, which guide the selection and placement of safety measures including protective eyewear and barriers.