Foundations of Laser Safety Compliance in Inspection Design

Aligning Inspection Protocols with ANSI Z136.1 and IEC 60825-1 for Laser Safety Assurance

Getting laser safety right starts with following the major global standards that exist for this purpose. ANSI's Z136.1 guideline covers important aspects of engineering controls like beam enclosures, those safety switches that stop operations when needed, and what kind of eye protection workers should wear based on their optical density needs. Meanwhile, the IEC 60825-1 standard handles things differently, setting out how lasers get classified, what tests need to be done, and where performance limits are set. When checking if everything meets these standards, inspectors need to look closely at all safety features against both sets of rules, especially making sure that eye protection works properly at different light wavelengths. A recent study published in the Journal of Laser Applications back in 2023 found that places which check against both standards see about 73% fewer compliance problems. This combined method helps keep workplaces safe no matter what kind of manufacturing setup they have going.

Integrating FDA/CDRH and EU CE Requirements to Enable Global Laser Safety Market Access

Getting products onto global markets means dealing with different regulations across regions. For companies selling in the United States, they need to work with the FDA's Center for Devices and Radiological Health (CDRH). The CDRH wants to see proper product registration, test results showing how well things work, and labels that tell customers exactly what they're getting according to rules in 21 CFR Part 1040.1. Things get even trickier in Europe where manufacturers must obtain CE markings under the Machinery Directive (2006/42/EC). This involves putting together detailed conformity assessments, creating comprehensive technical files, and implementing risk reduction plans aligned with ISO 13849-1 standards. Smart businesses set up inspection points that check multiple aspects at once like label accuracy, design docs, and how hazards are communicated to workers. These integrated checks save time and avoid redundant work. According to the latest Global Compliance Report from 2024, companies that adopt such streamlined approaches typically launch their products 40 percent quicker than those struggling with fragmented compliance processes.

In-Process Laser Safety Inspection: Critical Control Points and Automation

Lens Substrate Uniformity, Frame Integrity, and OD Marking Verification for Protective Eyewear

When it comes to protective eyewear, manufacturers run thorough checks on three main features during production: how uniform the lens material is, whether the frames hold up structurally, and if those permanent OD markings stay readable over time. They use spectrophotometers to make sure lenses transmit light consistently according to ANSI Z136.1 standards. Frames get put through stress tests to see how well they resist impacts and bending. For the OD markings, products go through multiple rounds of UV exposure to confirm they don't fade or become hard to read after being out in various environments for extended periods. Facilities that implement these quality controls regularly report about 22% fewer mistakes made by workers regarding improper eyewear usage, according to figures from an industry benchmarking group back in 2020.

Automated Optical Density Mapping and Real-Time Spectral Validation for Consistent Laser Safety Performance

The latest automation tech has made it possible to map optical density (OD) across all wavelengths in protective filters. Robots check the spectrum every 15 nanometers, making sure the actual light blocking matches what's required by the IEC 60825-1 standards for each specific wavelength. When real time monitoring detects anything outside of the ±0.1 OD range, alarms go off immediately. This threshold was set specifically for Class 4 lasers since even small failures in light blocking can cause serious eye damage. The whole system cuts down on hands-on inspections by about 40 percent and covers every single item produced. Facilities that run lots of lasers have seen injury rates drop by around 35% after installing this system back in 2019 according to their reports, which speaks volumes about how much safer operations become with proper monitoring in place.

Final Laser Safety Inspection: Verification of Labeling, Durability, and Traceability

Compliance Checks for Hazard Pictograms, OD Label Accuracy, and ISO 7010-conformant Nameplates

Before anything gets released, final checks happen to make sure everything is properly labeled, durable enough for real world use, and can be traced back if needed. Safety symbols need special attention during inspection since they must follow strict guidelines like ANSI Z136.1 and ISO 7010 standards. These symbols communicate radiation risks clearly so workers know what they're dealing with. When it comes to optical density (OD) labels, we compare them directly to actual test results. If there's even a small difference - more than plus or minus 0.2 OD units - then those items get rejected automatically. This cutoff point comes from recent studies showing what level of protection actually works in practice according to the Journal of Laser Applications from last year. Nameplates that meet ISO 7010 requirements go through tough tests for stickiness and wear resistance, simulating how they'd hold up after years in factories. Permanent Data Matrix codes are checked again after being exposed to chemicals to ensure they stay readable when auditors come around. Our automated vision systems catch problems like peeling or faded labels about 43 percent better than people could do by eye, which makes our quality control much stronger and helps stop fake products from getting into circulation.

Functional Laser Safety Validation: Interlocks, Redundancy, and Operational Reliability

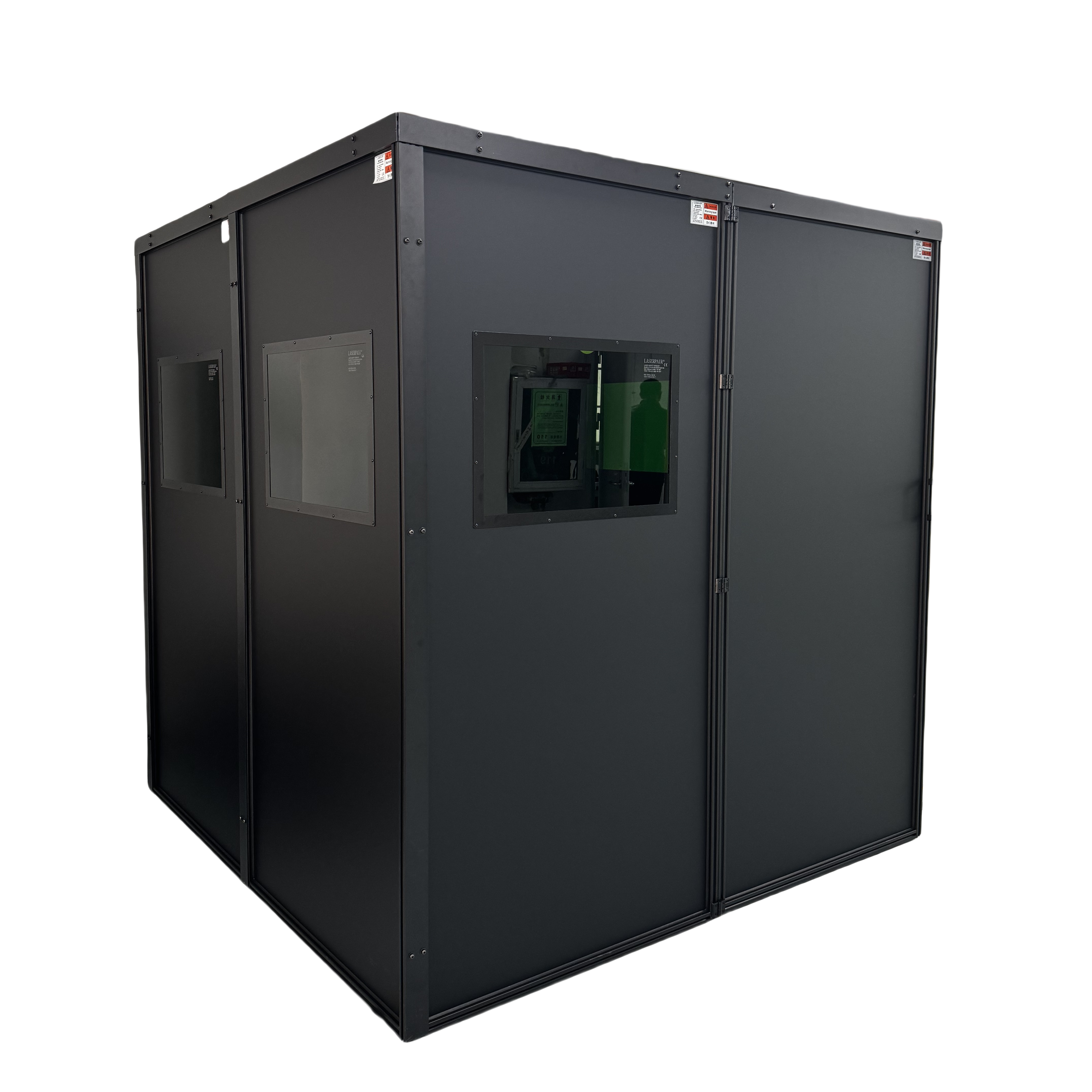

To check if laser safety works properly, we need to thoroughly test all the built-in protection features meant to stop dangerous exposures. The main safety mechanism here is the interlock system which turns off the laser automatically whenever someone opens the enclosure or hits an emergency stop button. These systems must shut down within half a second according to standards set by IEC 60825-1. For extra safety, most setups include redundant circuits following ISO 13849-1 guidelines so everything still works even if one part fails. There are also monitoring circuits running constantly to make sure those interlocks stay intact. We put these systems through their paces too, testing how they handle extreme temperatures, vibrations from machinery, and other physical stresses over time. Access controls can be programmed so only certain people get to turn on the lasers, and diagnostic tools keep tabs on overall system health. What makes this approach effective is that safety checks happen not just during normal operation but also when things go wrong - like power failures, drifting sensors, or broken wires. This creates a comprehensive safety network that stops problems before they occur instead of waiting for something bad to happen first.

FAQ

What are the key global standards for laser safety compliance?

The key global standards are ANSI Z136.1 and IEC 60825-1, which cover engineering controls, eye protection, and laser classification.

Why is it important to integrate FDA/CDRH and EU CE requirements?

Integrating these requirements is crucial for global market access, ensuring compliance with regional regulations, and speeding up the product launch process.

How do manufacturers ensure the durability of protective eyewear?

Manufacturers conduct stress tests on frames, use spectrophotometers for lens uniformity, and run UV exposure checks to ensure marking visibility over time.

What role does automation play in laser safety inspections?

Automation facilitates real-time spectral validation, reducing manual inspections, and enhancing laser safety by ensuring compliance with standards through mapping optical density.

How is operational reliability of laser systems ensured?

Operational reliability is ensured through testing interlocks, redundancy, and constant monitoring to prevent dangerous exposures and maintain system health.

Table of Contents

- Foundations of Laser Safety Compliance in Inspection Design

- In-Process Laser Safety Inspection: Critical Control Points and Automation

- Final Laser Safety Inspection: Verification of Labeling, Durability, and Traceability

- Functional Laser Safety Validation: Interlocks, Redundancy, and Operational Reliability

-

FAQ

- What are the key global standards for laser safety compliance?

- Why is it important to integrate FDA/CDRH and EU CE requirements?

- How do manufacturers ensure the durability of protective eyewear?

- What role does automation play in laser safety inspections?

- How is operational reliability of laser systems ensured?